Electric Hoists: The Precision Power of Industrial Lifting

In modern industrial production and logistics, electric hoists are indispensable lifting equipment. Their efficiency, precision, and safety make them a core feature of factories, warehouses, and construction sites. These electrically powered hoists, through the precise coordination of mechanical transmission and electronic control, enable flexible movement of heavy objects in three dimensions, significantly improving operational efficiency and safety.

I. Essential Analysis of Electric Hoists

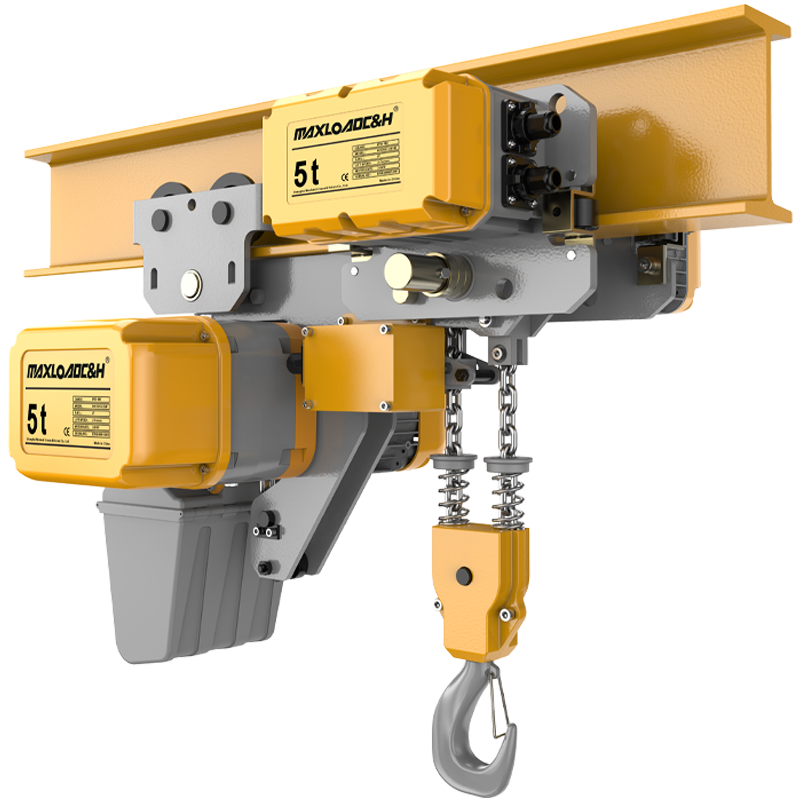

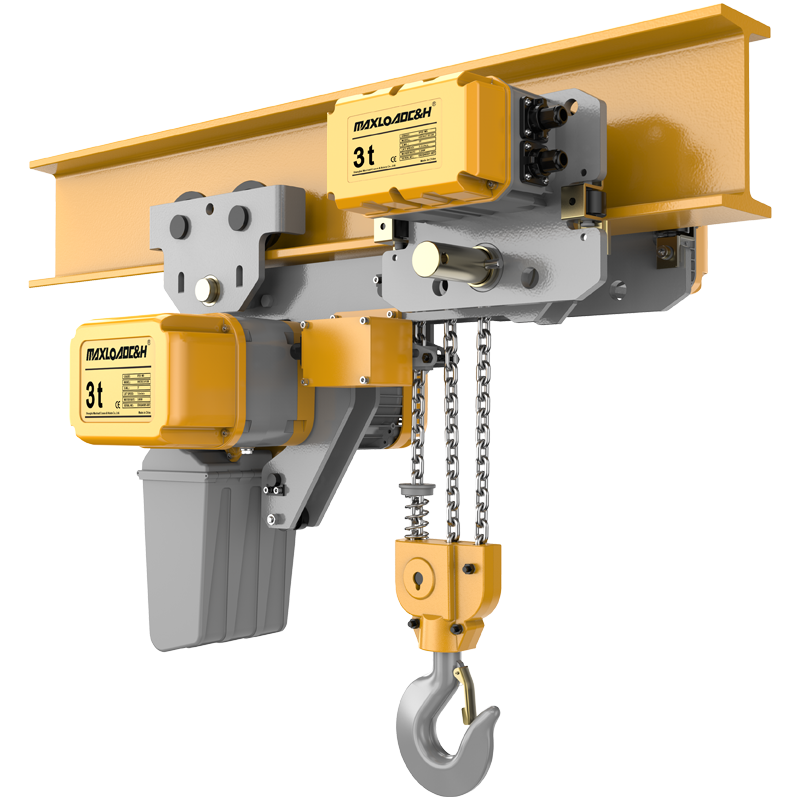

An electric hoist is a lightweight, compact lifting device that converts electrical energy into mechanical energy, enabling vertical lifting and horizontal movement via a wire rope or chain. Its core components include a drive motor, a reduction gear, a hoisting mechanism, a braking system, and a control unit. The motor, as the power source, reduces speed and increases torque through the reduction gear, driving the drum or sprocket. The brake quickly engages in the event of a power outage or abnormal condition, preventing the load from falling. The control unit enables intelligent operations, such as start/stop, speed regulation, and position limits, via buttons or a remote control. Compared to manual hoists, electric hoists are more mechanized, enabling continuous operation and precise positioning. Compared to large cranes, they are compact and flexible, making them suitable for space-constrained working environments.

II. In-Depth Analysis of Structural Design and Operating Principles

The structural design of electric hoists follows the logical chain of "power-transmission-execution-control." Taking a typical electric chain hoist as an example, the motor is connected to the reducer input shaft via a coupling. The reducer internally utilizes a multi-stage gear transmission, converting the high-speed, low-torque input into a low-speed, high-torque output, driving the sprocket. One end of the chain is fixed to the drum, and the other end is connected to the load via a hook. The chain's rotation enables lifting and lowering. Brakes are typically electromagnetic or conical. Electromagnetic brakes use spring force to brake the machine when power is off, while conical brakes utilize the self-locking properties of the friction cone surface to achieve an instant stop. Control system design reflects an evolution from simple to intelligent: early systems employed wired pushbutton control, while modern systems widely utilize wireless remote control, PLC programmable control, and IoT remote monitoring, enabling coordinated operation of multiple devices and fault warnings.

III. Diversified Application Scenarios

Electric hoists are used across all aspects of industrial production. In automotive manufacturing, they are used for lifting and assembling large components such as engines and gearboxes; in steel smelters, they handle the transfer of ladles and billets; at ports, they work with gantry cranes for rapid loading and unloading of containers; and on construction sites, they are used for vertical transport of building materials and equipment. Furthermore, in warehousing and logistics, electric hoists are combined with racking systems to form the core lifting unit of automated warehouses. On film and television sets, they utilize rail systems to position lighting and camera equipment precisely. This widespread cross-industry application stems from their three core advantages: lightweight design, high reliability, and easy maintenance.

IV. Quantitative Analysis of Technical Advantages

The technical advantages of electric hoists can be intuitively demonstrated through specific parameters. Taking an electric hoist with a rated load of 1 ton as an example, its standard lifting speed can reach 8 meters per minute, with positioning accuracy within ±5 mm. Motor power typically ranges from 1.5 to 3 kilowatts, with an energy efficiency rating of IE3 or higher. Brake response time is less than 0.2 seconds, ensuring safety during emergency stops. In terms of continuous operation capability, modern electric hoists utilize an S2 duty cycle (short-duty operation), enabling over 600 start-stop cycles per hour. In terms of environmental adaptability, they achieve an IP54 rating and can withstand a wide temperature range of -20°C to 60°C. These technical specifications are the result of the integrated application of multidisciplinary technologies, including materials science, motor control, and mechanical design.

V. A Scientific Maintenance System

The long-term and stable operation of an electric hoist depends on a scientific maintenance system. Routine maintenance includes lubrication of the wire rope/chain, adjustment of brake clearance, and functional testing of limit switches. Regular maintenance involves testing motor insulation, checking the reducer oil level, and measuring the insulation resistance of the control circuit. Preventive maintenance adopts a combined "planned maintenance + condition-based maintenance" model. Vibration monitoring, temperature detection, and oil analysis are used to proactively identify potential faults such as bearing wear and gear fatigue. Troubleshooting follows the principle of "diagnosis before repair," using fault codes to quickly locate the source of the problem and avoid secondary damage caused by blind disassembly.

VI. Future Technological Trends

Electric hoists are developing towards intelligence, greening, and modularization. In terms of intelligence, they integrate sensors, the Internet of Things, and AI algorithms to implement functions such as load-adaptive speed regulation, path planning, and remote operation and maintenance. In terms of greening, they utilize permanent magnet synchronous motors and variable frequency control technology to improve energy efficiency and reduce carbon emissions. In terms of modularity, standardized interfaces enable rapid replacement of power units, control units, and actuators, reducing maintenance costs and downtime. Furthermore, the application of cutting-edge technologies such as wireless power supply and magnetic levitation guides is driving the evolution of electric hoists towards contactless, ultra-quiet, and ultra-high-speed operation.

Conclusion

As the "precision muscle" of industrial lifting, the development of electric hoists has witnessed the innovative integration of mechanical engineering, electronics, and materials science. From initial manual operation to today's intelligent control, and from single functions to diverse applications, electric hoists have consistently prioritized safety, efficiency, and reliability, serving global industrial production and logistics. In the future, as new technologies continue to emerge, electric hoists will continue to evolve towards intelligent, green, and modularized systems. This seemingly simple lifting device embodies profound engineering wisdom and technological innovation, making it an indispensable force in the modern industrial system.

0086 17717607077

0086 17717607077

0086 (021) 5999 9072

0086 (021) 5999 9072

market@chnhoist.com

market@chnhoist.com