Electric Hoists: The "Light Cavalry" of Industrial Lifting

In modern industrial production, the efficiency and safety of material handling have a direct impact on the overall pace of production. As a representative of lightweight and compact lifting equipment, electric hoists, with their flexibility, efficiency, and ease of operation, have become indispensable "air assistants" in factory workshops, logistics warehouses, construction sites, and other settings. Like the "light cavalry" of the industrial sector, powered by electric drive, they precisely lift and horizontally move heavy objects within confined spaces, injecting powerful momentum into modern production.

I. The "Heart and Bones" of the Electric Hoist

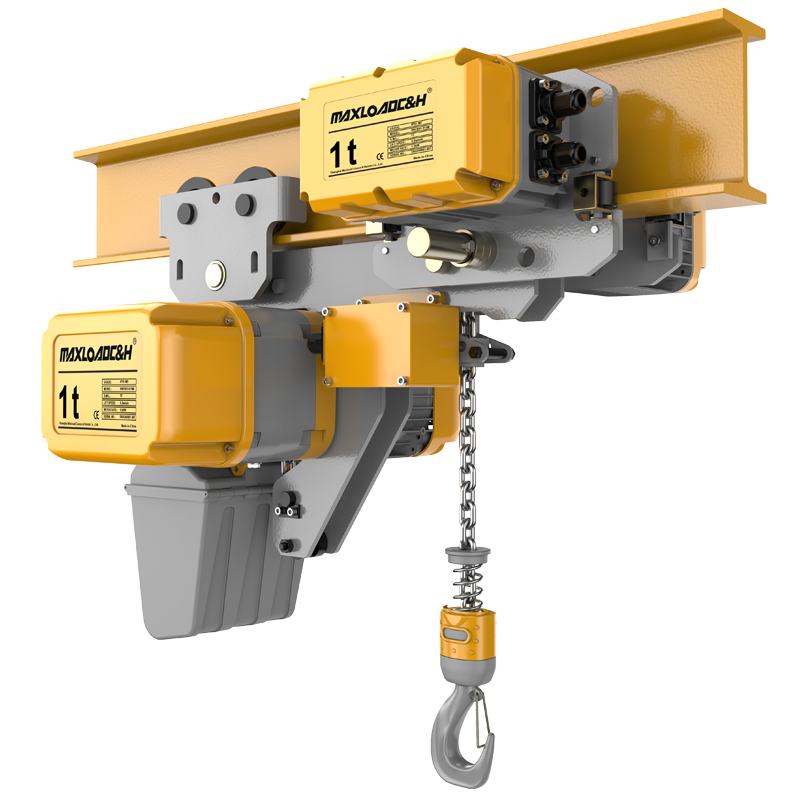

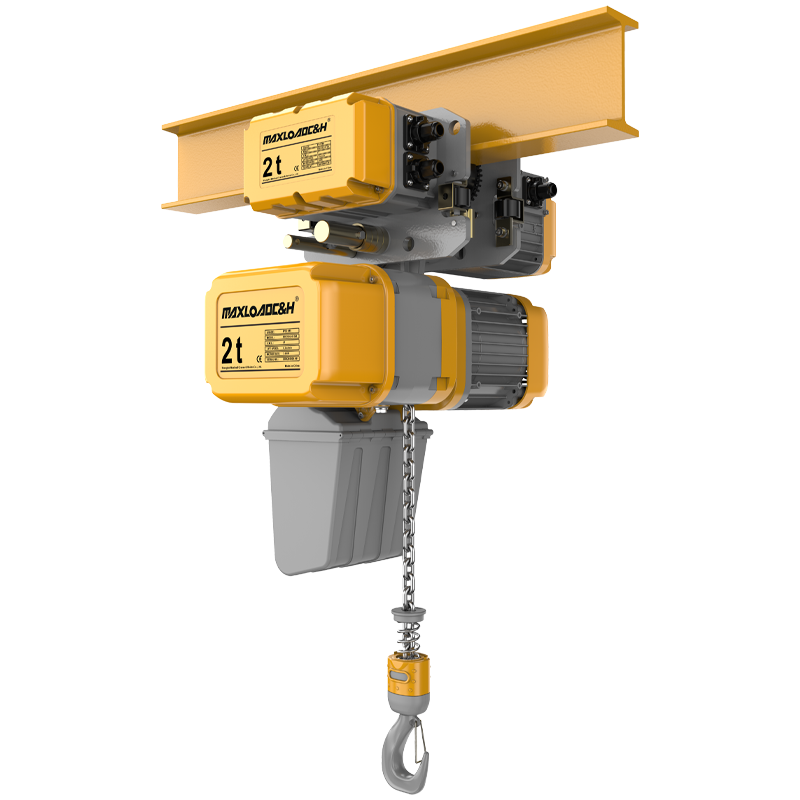

The structural design of the electric hoist embodies the wisdom of "small yet precise" industrial equipment. Its core consists of five modules: the motor, reducer, drum mechanism, hook mechanism, and electrical control system. These components work together to ensure the stable lifting of heavy objects.

Power Source: Motor

The motor of an electric hoist typically uses a conical rotor brake motor. This design integrates the brake mechanism within the motor. When the power is cut off, spring pressure forces the brake ring to press against the brake wheel, instantly stopping the machine and preventing the risk of the load slipping. The motor also features a soft-start function, which reduces current surges and extends equipment life.

Drive System: Reducer and Drum

The reducer reduces motor speed and increases torque through gear meshing, ensuring the drum rotates at a stable speed. The wire rope or chain wrapped around the drum is a critical component for carrying heavy loads, requiring high strength and fatigue resistance to withstand the rigors of frequent lifting.

Hook and Limit Device

As the component that directly contacts the load, the hook is typically forged from alloy steel and equipped with a safety catch to prevent unhooking. Upper and lower limiters control the lifting height using travel switches to prevent overloading or ceiling collisions, providing a double safeguard for operational safety.

Control Center: Electrical System

Modern electric hoists are often operated by remote control or push-button operation. Frequency conversion technology enables stepless speed regulation, ensuring smoother lifting and lowering. Some models also feature overload protection and phase loss protection, automatically shutting off power when current is abnormal to prevent equipment damage.

II. Flexible and Versatile "Application Map"

The adaptability of electric hoists makes them a provider of cross-industry solutions. Based on usage scenarios and load requirements, their applications can be divided into three major areas:

Factory Floors: "Aerial Arms" for Precision Assembly

In industries such as automotive manufacturing and machining, electric hoists are commonly used to lift heavy components such as engines and gearboxes. Their micro-motion function (with a minimum lifting speed of 0.8 m/min) enables millimeter-level positioning, helping workers complete high-precision assembly. For example, on the engine assembly line, electric hoists can precisely position engine modules weighing hundreds of kilograms onto vehicle frames with an accuracy of ±1 mm.

Logistics and Warehousing: "Space Managers" for Efficient Flow

In high-bay warehouses, electric hoists work together with single- and double-girder cranes to form an "aerial transport network." Traveling on rails, they can quickly move between shelves, storing and retrieving goods. Data from a large e-commerce warehouse shows that the introduction of electric hoists has increased cargo turnover efficiency by 40% and reduced manual handling costs by 60%. Construction Sites: A Multifaceted Tool for Temporary Lifting

From vertical transport of rebar and formwork to assisting with concrete pouring, electric hoists, thanks to their portability (some models weigh less than 100 kg), have become a vital tool on construction sites. Explosion-proof models can also be used in flammable and explosive environments like coal mines and chemical plants. Their flameproof motors and sealed design ensure safe operation in hazardous areas.

III. Balancing Safety and Efficiency

Electric hoists are designed with safety in mind. For example, a dual braking system (built-in motor brake + electromagnetic brake) ensures immediate locking upon power failure. Anti-loosening devices are installed at the ends of the wire ropes to prevent accidents caused by entanglement. Operating procedures are also crucial: check the limiter sensitivity before use, strictly avoid overloading (typically rated loads are 0.5-20 tons), and keep personnel away from under loads during lifting.

To enhance efficiency, electric hoists feature a modular design that allows for rapid maintenance. For example, the drum assembly features a quick-release structure, allowing wire rope replacement in just 10 minutes. The electrical box includes expansion ports for installing load cells or remote monitoring modules, enabling data-driven management. A steel company's experience has shown that through regular maintenance and operator training, the failure rate of electric hoists can be reduced by 75%, extending their service life to over eight years.

IV. "Electrification Upgrade" in Green Transformation

With the advancement of the "Dual Carbon" goals, electric hoists are undergoing technological innovation. Wireless models powered by lithium-ion batteries are now being used in field operations, freeing them from the constraints of power cords. Energy recovery systems convert braking energy into stored electrical energy, reducing energy consumption by over 20%. Furthermore, the use of lightweight materials (such as high-strength aluminum alloys) has reduced the equipment's weight by 30%, further expanding its potential for applications such as high-rise building and bridge maintenance.

V. The Future: Integration of Intelligence and Customization

The evolution of electric hoists is shifting from "single devices" to "intelligent systems." Leveraging IoT technology, devices can upload real-time operating data to the cloud. Managers can monitor parameters such as load and operating time via a mobile app, providing early warning of failures. Customized services are also becoming a trend. For example, dust-free electric hoists designed for cleanrooms utilize stainless steel and a sealed structure to prevent particulate contamination. Corrosion-resistant models are galvanized for use in harsh environments like offshore platforms.

Conclusion

From factories to construction sites, from logistics to energy, electric hoists carry a significant mission despite their compact size. They are not only tools for improving efficiency but also the epitome of industrial safety and intelligence. With the continuous advancement of technology, this "light cavalry" will continue to transcend application limitations, contributing to both efficiency and safety in a wider range of fields.

0086 17717607077

0086 17717607077

0086 (021) 5999 9072

0086 (021) 5999 9072

market@chnhoist.com

market@chnhoist.com