Lightweight Lifting Solutions in Modern Industry - Electric Hoists

Lifting equipment is an indispensable and critical component of modern industrial production systems. As a representative example of lightweight lifting equipment, electric hoists, with their compact structure, easy operation, and wide applicability, play a vital role in a variety of scenarios, including factory floors, logistics warehouses, construction sites, and ports. These electrically powered mechanical devices, which enable the lifting and lateral movement of heavy objects, not only improve operational efficiency but also continuously expand their application through technological innovation, becoming an essential technology in the advancement of industrial automation.

I. Basic Structure and Operating Principle

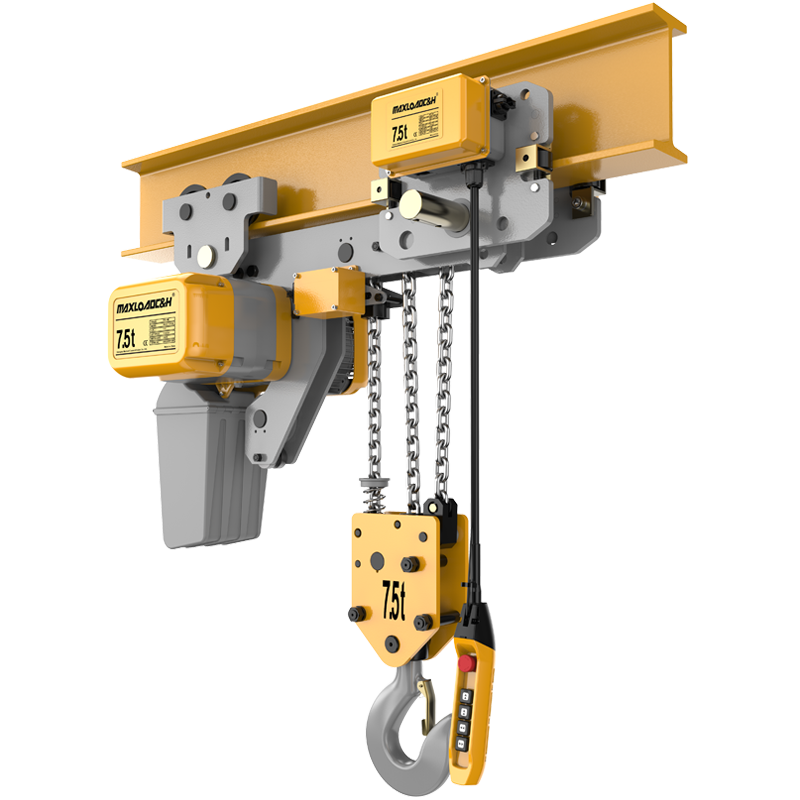

The core structure of an electric hoist consists of five major components: the drive system, transmission system, hoisting mechanism, operating mechanism, and electrical control system. The drive system typically utilizes a three-phase asynchronous motor or permanent magnet synchronous motor, which, through a speed reducer, converts high-speed rotation into low-speed, high-torque output to drive the drum or sprocket. The hoisting mechanism utilizes a wire rope or high-strength chain to lift the load vertically. Some models are equipped with a dual-speed motor for precise positioning. The operating mechanism uses a motorized trolley to achieve lateral movement on the I-beam track. Some portable models utilize manual push-pull assistance.

The operating principle is based on energy conversion and torque transmission: the mechanical energy output by the motor is increased in torque by a reducer, driving the drum to wind the wire rope or sprocket to wind the chain. This is achieved through a movable pulley system, which reduces effort and increases efficiency. Modern electric hoists are commonly equipped with limit switches, overload protection, and emergency braking systems, forming a multi-layered safety network. Limit switches automatically cut off power to prevent overwinding, and electronic overload protection uses pressure sensors to monitor the load weight in real time, automatically shutting down the machine and issuing an alarm when the rated load is exceeded.

II. Technological Evolution and Development Trends

The technological development of electric hoists can be traced back to the electrification of manual hoists in the late 19th century. In the mid-20th century, breakthroughs in motor technology and materials science enabled electric hoists to achieve both lightweighting and increased reliability. The use of carbon fiber-reinforced composite materials has reduced the weight of some high-end models by 30% while increasing their load capacity by 15%. The introduction of variable frequency speed regulation technology enables stepless adjustment of lifting speed, meeting the demands of precision assembly.

Currently, intelligence is a key development direction for electric hoists. By integrating IoT sensors, they enable real-time load monitoring, trajectory tracking, and fault warnings. Some high-end models are equipped with remote control systems, allowing operators to control the equipment from a distance of 50 meters via a handheld terminal, enhancing safety in hazardous environments. The modular design concept enables rapid replacement of core components such as motors and reducers, reducing repair time to less than two hours.

III. Analysis of Typical Application Scenarios

In the automotive manufacturing industry, electric hoists are used in key processes such as engine assembly, lifting, and material handling on body welding lines. Their precise positioning capabilities and stable lifting performance ensure efficient production line operation. In the warehousing and logistics industry, electric hoists used in conjunction with single-girder cranes can facilitate vertical transport of goods from the ground to shelves. Combined with automated guided vehicles (AGVs), they enable intelligent "goods-to-person" warehousing.

On construction sites, electric hoists are commonly used for high-altitude operations such as curtain wall installation and steel structure hoisting. Its portable design allows for single-person operation, and generator power can be used in areas without power. In ports and terminals, marine electric hoists, with their salt spray corrosion resistance, handle heavy tasks such as container loading and unloading and ship repair. In the power industry, specialized maintenance electric hoists can be moved along rails to designated locations to perform maintenance and hoisting operations on equipment such as transformers and circuit breakers.

IV. Safe Operation and Maintenance Specifications

Safe operation is the core principle of electric hoist use. Operators must undergo professional training and be familiar with equipment performance parameters and emergency response procedures. Before lifting, the wire rope should be inspected for wear, the effectiveness of the limit devices, and the insulation of the electrical circuits. Overloading is strictly prohibited during lifting, and standing under the load or lifting at an angle or angle is prohibited.

Daily maintenance includes regular lubrication of key components, checking brake clearance, and testing the overload protection device. A comprehensive inspection should be conducted quarterly, including motor insulation testing, wire rope break detection, and control system functionality verification. Maintenance records should detail equipment operating hours, maintenance details, and part replacements, forming a complete equipment record.

V. Technical Challenges

The main technical challenges currently facing electric hoists include improving energy efficiency, reducing operating noise, and enhancing environmental adaptability. The application of permanent magnet synchronous motor technology has enabled some models to achieve IE4 energy efficiency standards, saving 20% energy compared to traditional asynchronous motors. By optimizing gearbox design and employing silent bearings, operating noise can be controlled below 65 decibels, meeting the requirements of indoor working environments.

Future development will focus on green, intelligent, and modularization. The integration of solar power systems enables zero-carbon emissions for outdoor operations, and energy recovery technology converts braking energy into stored electrical energy. The application of 5G communication technology will enable remote monitoring and fault diagnosis of equipment, and predict equipment lifecycles through big data analysis. Modular design will promote plug-and-play component replacement and improve equipment maintainability.

As the "micro-lifting expert" in industrial production, electric hoists are constantly pushing the boundaries of traditional applications through continuous technological innovation and expanded application scenarios. From factory floors to construction sites, from logistics warehouses to port terminals, this lightweight lifting equipment, with its efficient, safe, and intelligent features, continues to drive changes in industrial production methods and has become an indispensable component of the modern industrial system. With the continuous emergence of new materials and new processes, electric hoists are poised for even greater development and will play an even more crucial role in the wave of intelligent manufacturing.

0086 17717607077

0086 17717607077

0086 (021) 5999 9072

0086 (021) 5999 9072

market@chnhoist.com

market@chnhoist.com