Electric Hoist: The Silent Assistant in Lifting Operations

In busy construction sites, orderly production workshops, and warehouses and docks piled high with goods, a quiet yet powerful presence is often suspended from an I-beam track, precisely lifting and lowering various heavy objects – this is the electric hoist, an indispensable mechanical device in modern industrial material handling. As an efficient and reliable lifting tool, the electric hoist is widely used in various industries due to its compact structure, simple operation, and strong adaptability, becoming an important piece of equipment for improving work efficiency and reducing labor intensity.

I. Working Principle and Technical Characteristics of Electric Hoists

The core working principle of an electric hoist is to convert the rotational motion of the electric motor into the linear lifting and lowering motion of the hook. When the power is switched on, the electric motor starts to rotate, and the speed is reduced and the torque is increased through a gear reduction mechanism, driving the drum or sprocket to rotate, thereby winding the wire rope or chain to lift or lower the heavy object. The control system usually includes various methods such as conventional button control, remote control operation, or automated program control.

1. Compact structure: The electric hoist integrates the drive, transmission, and control systems within a limited space, without occupying excessive space.

2. High efficiency: Compared with manual or hydraulic drives, electric drives have a quick response and fast lifting speed, significantly improving work efficiency.

3. Simple operation: It can be easily controlled through buttons or a remote control, reducing the skill requirements for operators.

4. Safe and reliable: Modern electric hoists are equipped with multiple safety devices, such as upper and lower limit switches, overload protection, and emergency braking.

5. Strong adaptability: Parameters such as lifting capacity, lifting height, and working level can be customized according to different needs, adapting to diverse scenarios.

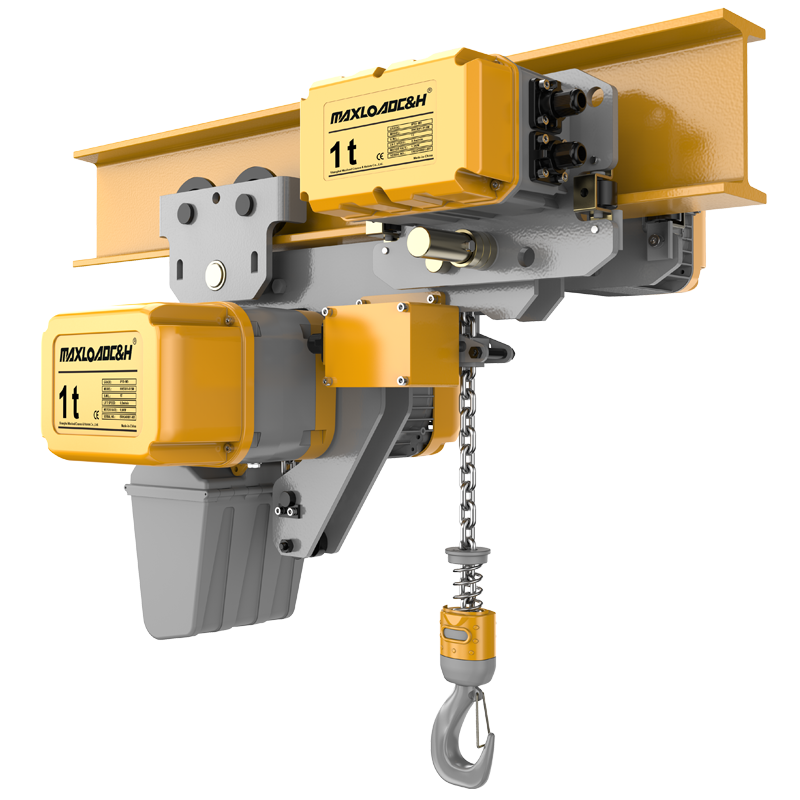

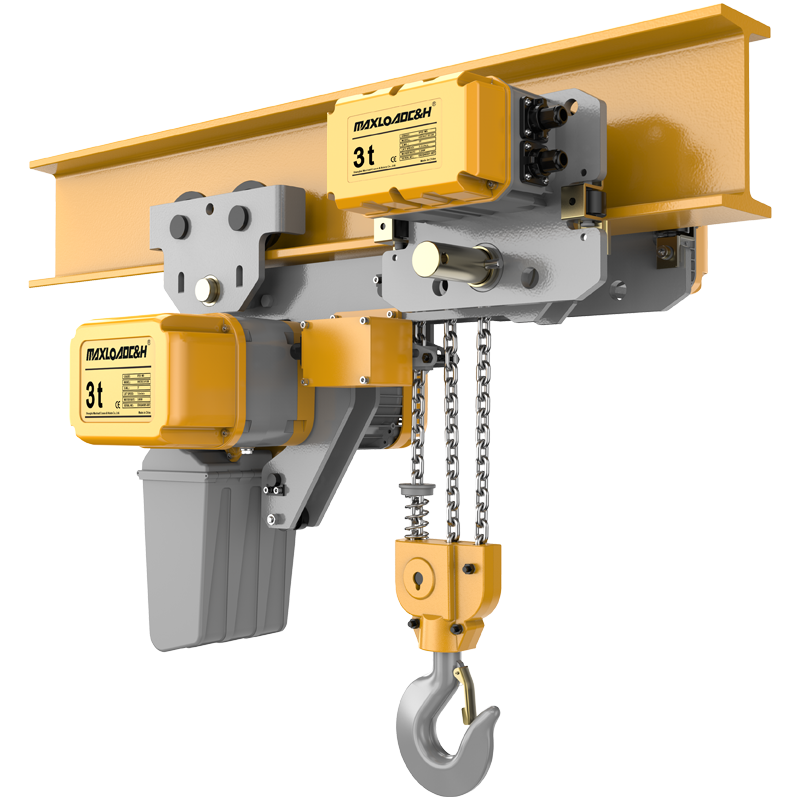

II. Key Components of Electric Hoists

1. Power System

The electric motor is the heart of the electric hoist, providing the power required for lifting and moving. Depending on the operating environment and requirements, ordinary, explosion-proof, or special protective motors can be used. Modern electric hoists are increasingly using variable frequency control technology to achieve smooth starting, precise positioning, and energy-saving operation.

2. Transmission System

The reduction mechanism converts the high speed and low torque of the electric motor into the low speed and high torque required by the drum. The gearbox design directly affects the hoist's load capacity, smooth operation, and service life. High-quality materials and precision machining are crucial for ensuring the reliable operation of the transmission system.

3. Load-Bearing System

The load-bearing system consists of the wire rope or chain and its winding mechanism. Wire ropes are characterized by good flexibility and high load capacity; chains are more wear-resistant and heat-resistant, suitable for harsh environments. The hook, as the component directly connected to the heavy object, has its material, structure, and heat treatment process directly affecting safety performance.

4. Control System

From simple button controls to advanced remote control and automation systems, control technology is constantly evolving. Modern electric hoists are increasingly integrating sensors and intelligent control units to achieve status monitoring, fault diagnosis, and preventive maintenance.

5. Safety Protection System

This includes limit switches, overload limiters, braking devices, phase protection, etc., forming a multi-layered safety protection network.

III. Application Fields of Electric Hoists

Electric hoists are used in almost all industrial fields that require vertical material handling:

Manufacturing: Used in production lines of automobiles, machinery, electronics, etc., for parts handling, equipment installation, and maintenance.

Construction: Used for lifting building materials, formwork, and construction equipment at construction sites.

Logistics and Warehousing: Used in warehouses for loading and unloading, stacking, and sorting goods.

Power Industry: Used for installation, inspection, and maintenance of power plant equipment.

Metallurgical Industry: Used for handling high-temperature materials in steelmaking and casting workshops.

Shipbuilding: Used for lifting ship sections and equipment installation.

Aerospace: Plays an important role in aircraft maintenance and component assembly.

In addition, electric hoists also have specialized applications in special fields such as stage equipment, sewage treatment, and mining.

IV. Selection and Usage Considerations for Electric Hoists

Choosing the right electric hoist is crucial for ensuring operational safety and improving work efficiency. The following factors should be considered during selection:

Lifting Capacity: Determined based on the maximum lifting weight, with a certain safety margin.

Lifting Height: Meets the actual lifting distance requirements, considering the safe distance between the hook's limit position and obstacles.

Working Class: Select the appropriate working class based on the frequency of use and load conditions.

Installation Environment: Consider special requirements such as temperature, humidity, corrosiveness, and explosion protection. Power supply requirements: Match the voltage, frequency, and power capacity of the site.

Control method: Select manual, remote, or automatic control according to operational needs.

When using an electric hoist, the following must be observed:

Operators must be professionally trained and familiar with equipment performance and operating procedures.

Regular inspection and maintenance are required to ensure that all components are in good condition.

Strictly adhere to the rated load; overloading is strictly prohibited.

Observe the equipment's operating status; stop the machine immediately and inspect it if any abnormality is found.

Establish a comprehensive equipment file and maintenance record.

V. The Value of Electric Hoists in Modern Industry

As basic lifting equipment, electric hoists create irreplaceable value in modern industrial production:

Improved production efficiency: Fast and precise material handling significantly shortens production cycles.

Reduced labor intensity: Mechanized operations replace manual handling, improving working conditions.

Ensured operational safety: Standardized operation and professional equipment reduce the safety risks of manual handling.

Optimized space utilization: Overhead transportation frees up ground space, improving site utilization.

Reduced overall costs: High-efficiency operations reduce equipment investment and labor costs, increasing return on investment.

Conclusion

From simple manual hoists to modern intelligent electric hoists, this seemingly ordinary lifting equipment has witnessed the continuous progress of industrial technology. In the future, with the further development of new materials, new processes, and intelligent control technologies, electric hoists will continue to evolve, better serving various industrial fields and becoming an important force in improving production efficiency and ensuring operational safety. For any industry involving material handling, understanding and correctly applying electric hoist technology will directly translate into competitiveness and safety assurance.

Whether it's planning for new projects or upgrading existing equipment, choosing the right electric hoist and using and maintaining it correctly is an indispensable part of enterprise facility management. Only by fully understanding the technical characteristics and application requirements of this equipment can its value in modern industrial production be truly realized, providing strong support for the safe and efficient operation of enterprises.

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

kimliu@chnhoist.com

kimliu@chnhoist.com