How Electric Hoists Shape Modern Production Landscapes

On a bustling construction site, a heavy steel component is quietly lifted and precisely positioned; on an automated production line, precision equipment is smoothly hoisted and moved to the next stage; in the vast, multi-tiered shelves of a logistics warehouse, tons of goods flow efficiently and in order. In these scenarios, a common key piece of equipment is silently playing a crucial role—the electric hoist, this unsung hero of the industrial field, has become an indispensable assistant in modern industrial production with its excellent lifting capacity and flexible control.

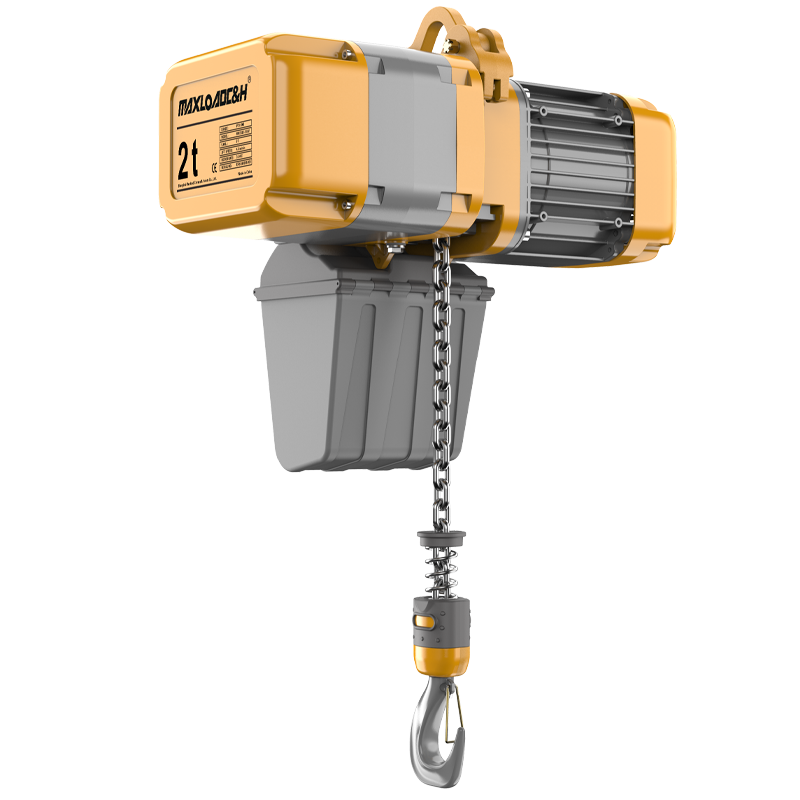

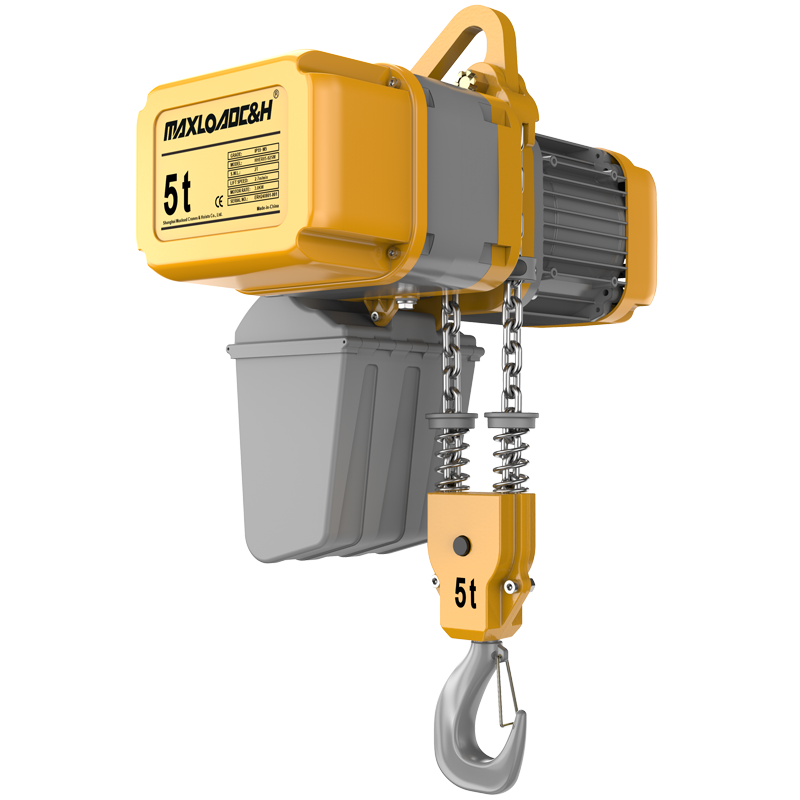

The electric hoist, as a widely used light and small lifting device, mainly consists of core components such as the electric motor, transmission mechanism, drum, and hook. Its birth was not instantaneous, but rather the culmination of long-term development in the mechanical industry. As early as the Industrial Revolution, lifting devices combining human power and simple machinery had already appeared. With the invention and application of electric motors, traditional manual hoists gradually evolved into electrically driven ones, resulting in a qualitative leap in work efficiency. Since the 20th century, with the continuous advancement of materials science, control technology, and safety standards, electric hoists have undergone continuous optimization in structural design, safety performance, and ease of operation, gradually becoming core equipment for material handling in various industries.

Delving into the internal structure of the electric hoist, we can find a precise power transmission system. Its core working principle begins with the electric motor—when powered on, the motor rotor rotates at high speed, and the torque generated is transmitted to the reducer through a coupling. The reducer, like a car's gearbox, converts high speed and low torque into low speed and high torque through multi-stage gear transmission. This process is crucial, ensuring sufficient lifting force and stable operating speed required for lifting operations. The power, after reduction and torque increase, finally drives the drum to rotate, allowing the steel wire rope or chain wound around it to be orderly wound and unwound, thereby achieving the lifting and lowering of heavy objects through the hook.

Safety is the lifeline of lifting operations, and modern electric hoists are meticulously designed with safety in mind. The overload protection device acts like a vigilant sentry, automatically cutting off the power supply when the load exceeds the rated capacity, preventing equipment damage and accidents. The limit switch acts as an "electronic guardrail," automatically stopping operation when the hook reaches the highest or lowest preset position, avoiding collisions and over-winding. The braking system is paramount for safety, typically employing a combination of electromagnetic and mechanical braking. Even in the event of a power outage, it responds immediately, securely locking the heavy load and preventing accidental slippage. Furthermore, many electric hoists are equipped with multiple safety features such as phase sequence protection, emergency stop buttons, and anti-collision devices, collectively forming a comprehensive safety net.

The applications of electric hoists are surprisingly wide-ranging. In manufacturing workshops, they are responsible for machine tool installation, mold lifting, and material supply on assembly lines; in construction projects, they participate in steel structure lifting, building material transportation, and equipment installation; in the logistics and warehousing industry, they assist in rack access, container loading and unloading, and cargo sorting; in the power maintenance field, they assist in transformer installation and line equipment replacement; and even in automotive repair shops, they are invaluable tools for lifting engines and moving parts. Based on specific operating environments and needs, electric hoists have evolved into various types: wire rope electric hoists offer high strength and large load capacity, suitable for heavy lifting; chain electric hoists have a compact structure and light weight, ideal for confined spaces; explosion-proof electric hoists are designed for hazardous environments such as oil and chemical industries; and low-headroom electric hoists effectively utilize limited height space, increasing the effective lifting distance.

To fully utilize the performance of electric hoists and ensure operational safety, correct selection, installation, and maintenance are crucial. Selection requires considering parameters such as rated lifting capacity, lifting height, working class, operating speed, and operating environment. Installation must strictly follow specifications, ensuring the track is level, the structure is stable, and the electrical wiring is correct. Routine maintenance includes regularly checking the wear of the wire rope or chain, brake performance, and electrical component status, timely lubricating moving parts, and establishing maintenance records to document operating conditions. Operators must receive professional training, be familiar with equipment performance, master hand signals or remote control operation, and adhere to the "ten no-lifting" principles—such as no lifting overloaded loads, no lifting with unclear signals, and no lifting with insecure bindings—and other basic safety guidelines.

In recent years, with the advancement of Industry 4.0 and intelligent manufacturing, electric hoists have also undergone a new round of technological innovation. The trend towards intelligence is becoming increasingly evident: the application of variable frequency control technology enables smoother starting and stopping and more precise positioning, significantly reducing material sway; remote monitoring systems collect real-time operating data through sensors, enabling fault warning and preventive maintenance; IoT technology makes collaborative operation of multiple hoists possible, improving overall logistics efficiency; lightweight design and the application of new materials reduce equipment weight while maintaining strength. These innovations not only improve the performance of individual units but also integrate electric hoists into the overall material flow of smart factories, becoming intelligent nodes in the smart manufacturing ecosystem.

Looking ahead, electric hoists will continue to evolve towards greater intelligence, safety, and efficiency. Modular design will improve customization efficiency, the introduction of artificial intelligence algorithms is expected to enable adaptive lifting and path planning, and the application of new energy sources, such as lithium batteries, will enhance equipment mobility and environmental friendliness. Meanwhile, virtual reality technology may be used for operator training, and digital twin technology will enable full lifecycle management of equipment. It is foreseeable that this "unsung hero" will continue to evolve in the wave of automation and digitalization, supporting more complex industrial needs with even greater capabilities.

From traditional manufacturing to smart factories, from construction sites to logistics hubs, electric hoists, with their reliable power and precise control, silently support the flow of materials in modern society. They may be inconspicuous, but they are everywhere; they may be unassuming, but they handle heavy loads with ease. In the grand narrative of industrial development, the story of the electric hoist is an enduring chapter about technological innovation, unwavering commitment to safety, and continuous improvement in efficiency—a compelling story written with steel and intelligence, about how to better improve our world.

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

kimliu@chnhoist.com

kimliu@chnhoist.com