Electric Hoists: The Core Power and Intelligent Evolution in Industrial Lifting

In the workshops of modern factories, on busy construction sites, and between the high-rise shelves of logistics warehouses, we can always see them – these compact, incredibly powerful devices, like tireless steel arms, effortlessly lifting, precisely moving, and smoothly placing hundreds of kilograms or even tens of tons of heavy objects. These are electric hoists, indispensable key equipment in modern industrial production and material handling. From simple heavy lifting to complex assembly lines, electric hoists, with their efficiency, reliability, and flexibility, have profoundly changed the way humans handle heavy objects, becoming an invisible force driving industrial civilization forward.

I. Understanding Electric Hoists:

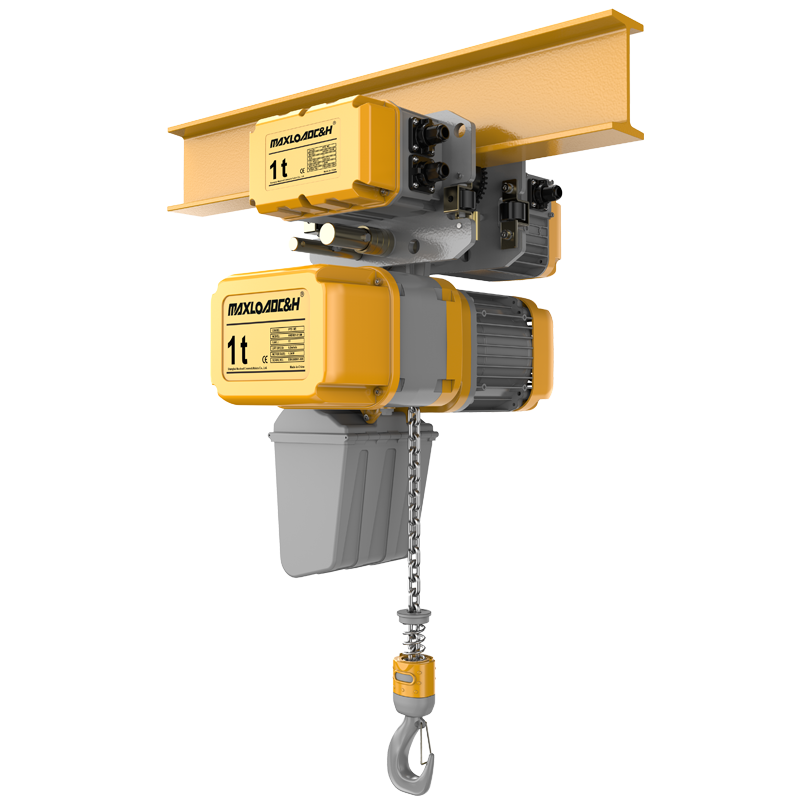

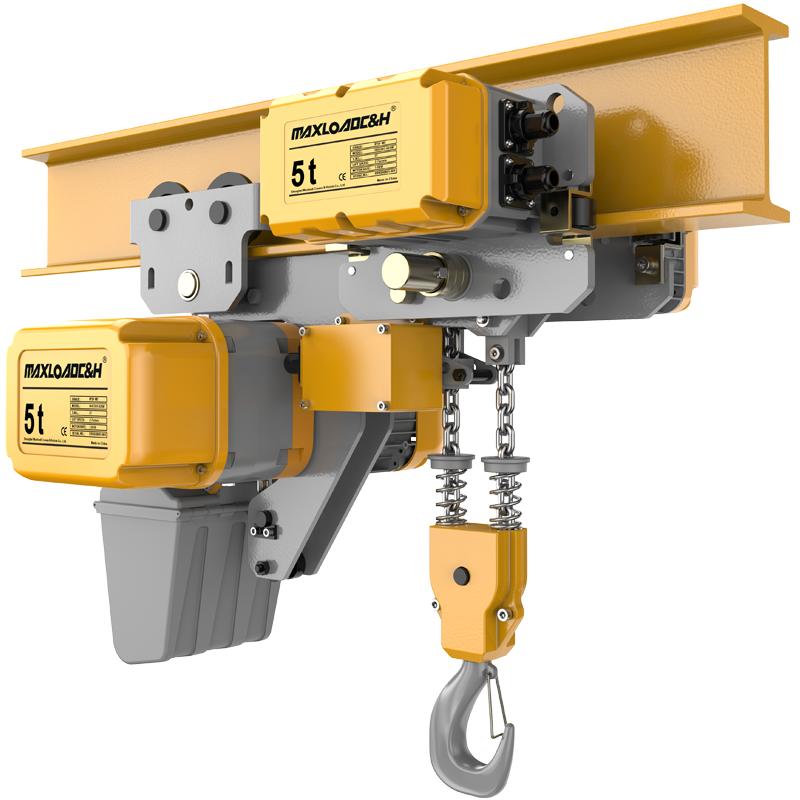

An electric hoist, as the name suggests, is a light and small lifting device driven by electricity. It is typically installed on a fixed I-beam track or integrated into lifting machinery, such as gantry cranes and jib cranes, allowing for linear or curved lifting and conveying operations within a specified range. Its basic mission is to vertically lift and horizontally move heavy objects, greatly saving manpower, improving work efficiency, and enhancing safety.

A typical electric hoist can be considered a precisely coordinated "life system":

The Heart of Power – The Electric Motor: As the primary energy source of the equipment, it typically utilizes a specially designed three-phase asynchronous motor for lifting and metallurgical applications, characterized by high starting torque, robust overload capacity, and an intermittent duty cycle, ensuring reliability during heavy-load starts and frequent starts and stops.

The Pulse of Transmission – The Reduction Mechanism: The high speed of the electric motor must be converted into the low speed and high torque output required by the hook. A multi-stage gear reduction gearbox undertakes this important task, and its manufacturing precision directly affects transmission efficiency, noise level, and service life.

The Core of Lifting – The Drum and Wire Rope/Chain: The drum winds the load-bearing component. Wire rope hoists use flexible and high-strength multi-strand or non-rotating wire ropes, suitable for medium to high lifting heights and larger tonnages. Chain hoists use high-strength alloy chains that have undergone rigorous heat treatment, resulting in a more compact structure, especially suitable for low-height spaces. The crucial lifting device – the hook – is typically forged from high-toughness alloy steel and equipped with a safety latch to prevent the load from slipping off.

The control center – the electrical system: This includes controllers for the lifting and traveling motors, contactors, limit switches, emergency stop devices, and handheld or remote control operators. Modern hoists also integrate safety features such as thermal protection and phase protection.

The safety shield – the braking system: This is paramount for safety. It commonly uses disc electromagnetic brakes or mechanical brakes of conical rotor motors to ensure that the load is reliably and immediately stopped when power is cut off, or a stop command is issued, preventing the heavy object from sliding down.

II. Solutions to Meet Diverse Needs

The working principle of electric hoists is clear and efficient: the operator issues commands via control buttons, the electrical system connects the power to the motor, and the motor's rotational power is significantly increased and reduced by the reducer, driving the drum to rotate, thus winding or unwinding the wire rope/chain, achieving the lifting and lowering of the hook and the load. For traveling hoists, the traveling motor drives the hoist to move laterally on the track via the trolley wheels.

Based on different technical approaches and application characteristics, electric hoists are mainly divided into two categories:

Wire rope electric hoists: These use flexible wire ropes as the load-bearing medium. Their advantages include high lifting height, relatively light weight, and smooth operation, with good compatibility with the drum, making them suitable for most general lifting applications, such as workshops, warehouses, and docks.

Chain electric hoists: These use high-strength alloy chains. Their main characteristics are an extremely compact structure and light weight, making them particularly suitable for space-constrained situations, such as low-ceiling factories, equipment maintenance, and fixed-point lifting on production lines. Their chain winding and unwinding mechanism provides good centering performance and flexible installation.

According to function, they can be divided into fixed and traveling types. Traveling hoists have different configurations depending on the track type (I-beam, H-beam, etc.) and driving method.

III. Key Steps to Matching Needs

Choosing the right electric hoist is the prerequisite for ensuring safety, efficiency, and cost-effectiveness. Selecting the right electric hoist is a rigorous "matching" process that requires considering the following core parameters:

Rated Lifting Capacity: Must be greater than or equal to the maximum static load required for daily lifting, and possible dynamic load factors must be considered. Overloading is strictly prohibited.

Lifting Height: The effective vertical distance from the upper limit to the lower limit of the hook. This needs to be determined based on actual working conditions, with a certain safety margin.

Working Class: Reflects the workload and load conditions of the equipment. International standards classify hoists into M1 to M8 classes based on usage time and load rate. Higher working-class hoists should be selected for frequent use and high-load-rate environments, as they have greater design redundancy in their motors, electrical controls, and mechanical components.

Operating Speed: Includes lifting speed and traveling speed. High speeds are required for efficient cycles in production lines; low speeds or even dual-speed/variable frequency control are needed for precise positioning in precision assembly or handling of fragile goods.

Operating Environment: Normal temperature workshops, high-temperature furnace areas, high-humidity coastal areas, dusty areas, chemical explosion-proof areas, or food and pharmaceutical clean areas all have completely different requirements for the hoist's protection level, insulation level, materials, and surface treatment.

Installation Method and Track Matching: Determine whether it is a fixed lifting point or a traveling type; the track gauge and track model of the traveling type must match the hoist's trolley frame.

In terms of application areas, electric hoists have long permeated every corner of industry: used in mechanical manufacturing workshops for lifting workpieces and molds; in assembly lines for conveying and positioning components; in warehouses for loading, unloading, and stacking goods; in auto repair shops for lifting engines; in power plants and waterworks for valve installation and maintenance... the boundaries of its application scenarios are constantly expanding.

IV. Safety Regulations and Maintenance

Safety is an insurmountable red line in lifting operations. Operators must be trained and familiar with the equipment's performance; visual inspections must be performed before each use; oblique pulling and lifting, passing over people, and overloading are strictly prohibited; after operation, the hook should be raised to the upper limit position and the main power supply should be switched off.

System maintenance is essential for extending lifespan and preventing failures. A regular maintenance system should be established: daily routine inspections; monthly checks of brake performance, wire rope wear, and chain elongation; annual comprehensive inspection, lubrication, and adjustment by professional personnel. If serious problems such as excessive wire rope breakage, plastic deformation of the chain, or brake failure are discovered, the equipment must be immediately taken out of service and repaired or replaced.

Looking ahead, electric hoists are evolving towards intelligence, environmental friendliness, ultimate safety, and user-friendliness:

Intelligence: Integrating sensors, PLC control, and IoT modules to achieve real-time status monitoring, predictive maintenance, fault self-diagnosis, remote management, and data uploading, integrating into smart factory systems.

Green and efficient: Adopting higher energy efficiency motors and optimized transmission designs to reduce energy consumption; promoting variable frequency speed control technology to achieve smooth starting and stopping and precise control, reducing mechanical shock and energy waste.

Modularity and lightweight design: Through structural optimization and the application of new materials, reducing self-weight while ensuring strength, facilitating installation and transportation, and further reducing overall dimensions.

Ergonomics and safety redundancy: More ergonomically designed remote controls and backlit buttons; multiple braking systems, intelligent anti-sway technology, and more precise limit protection will elevate safety to a new level.

From simple tools replacing manual labor to sophisticated execution units integrated into intelligent networks, the evolution of electric hoists is a microcosm of industrial technological progress. It is not only an extension of power but also a brilliant crystallization of human wisdom in solving the age-old problem of vertical handling. In the tide of Industry 4.0 and intelligent manufacturing, this reliable "steel hand" will continue to support the future of modern industrial production with a smarter, safer, and more efficient appearance.

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

kimliu@chnhoist.com

kimliu@chnhoist.com