Efficient Collaborative Solutions for Industrial Material Handling

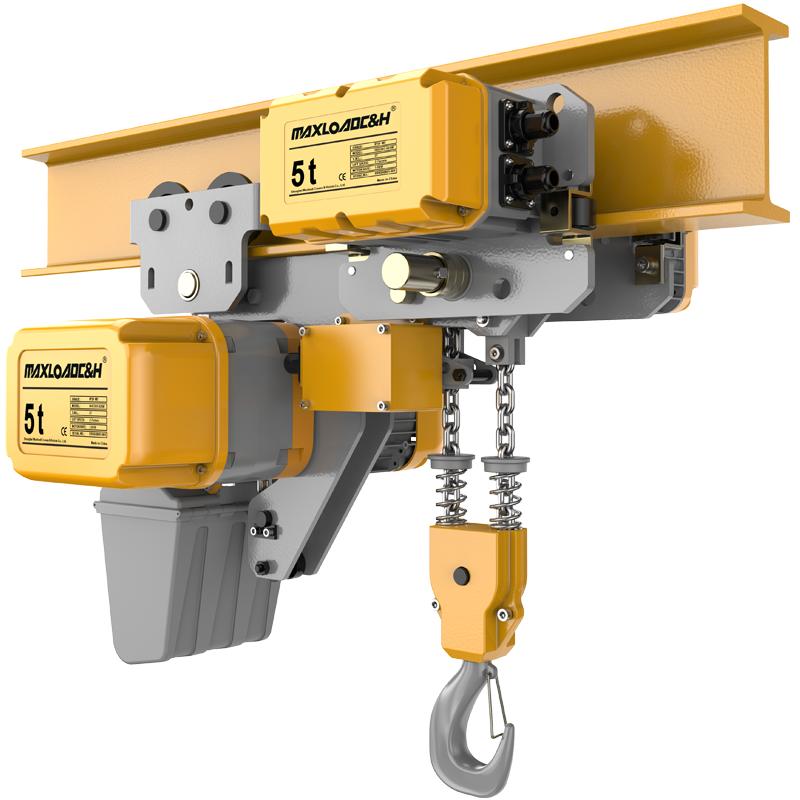

In modern industrial production workshops, warehousing and logistics, assembly lines, and even large-scale infrastructure construction sites, an efficient and reliable material handling system is a core element in ensuring smooth operations, improving production efficiency, and guaranteeing workplace safety. Among these, the combination of electric hoists and overhead cranes is arguably the most widely used and classic lifting solution. They are not simply a combination of equipment, but rather, through complementary functions and collaborative operation, they build a flexible and powerful handling network covering a three-dimensional space.

I. Collaborative Advantages: Synergistic Effects that Make One Plus One Greater Than Two

When an electric hoist is installed as the lifting mechanism on the trolley of an overhead crane, a complete bridge crane system is formed. This combination produces significant synergistic effects:

1. Full three-dimensional space coverage, greatly increasing the operating range: The longitudinal movement of the crane, the lateral movement of the trolley, and the vertical movement of the electric hoist together achieve precise positioning at any point in the three-dimensional space of the work area. Materials can be lifted from point A, transported smoothly and accurately via an aerial path, and lowered at point B, completely avoiding the influence of ground obstacles.

2. Optimized workshop layout, freeing up ground space: All major handling activities are completed in the air, allowing the workshop floor to be used more efficiently for equipment layout, product turnover, and personnel movement, avoiding congestion and safety hazards caused by ground handling tools, resulting in a cleaner factory layout and smoother logistics.

3. Improved handling efficiency and automation potential: Compared with simple ground handling, aerial lifting paths are more direct and faster. This advantage is particularly evident for heavy, bulky, or unusually shaped materials. Furthermore, the system is easily integrated with automated control systems, allowing for semi-automatic or fully automatic operation through preset programs or wireless remote control, further reducing labor requirements and improving operational continuity and consistency.

4. Enhanced operational safety and controllability: Professional electric hoists and overhead crane designs feature multiple safety protection devices, such as overload limiters, upper and lower limit switches, emergency stop devices, and anti-collision systems. Operators can clearly observe the entire lifting process from a safe position through ground-following operation, cab operation, or remote control, achieving stable and precise control of the load and significantly reducing the risks of direct manual handling.

5. Reduced labor intensity and improved working environment: Workers are freed from heavy and dangerous manual handling, allowing them to focus on higher value-added tasks such as assembly, inspection, and control, reflecting the people-oriented modern industrial concept.

II. Typical Application Scenarios: The Ubiquitous Handling Partner

The combination of electric hoists and overhead cranes is found in almost all areas requiring heavy or frequent material handling:

Manufacturing workshops: Used for loading and unloading machine tools, transferring parts between production lines, installing and replacing molds, and warehousing finished products.

Assembly and repair workshops: Used for lifting and positioning precision components on large equipment assembly lines; used in repair workshops for lifting equipment or assemblies awaiting repair.

Warehousing and logistics centers: Used for stacking, picking, and loading/unloading vehicles in raw material warehouses, semi-finished product warehouses, or finished product warehouses, especially suitable for handling unitized pallets or containers.

Steel and metallurgical industries: Lifting heavy and high-temperature materials such as steel coils, ingots, and molds, usually requiring specially protected metallurgical hoists.

Power plants: Used for installing and maintaining generators, turbines, boilers, and large components within nuclear islands.

Infrastructure construction and prefabricated building factories: Handling large concrete components in prefabricated component factories; used on construction sites for lifting rebar, formwork, and other materials.

III. Key Considerations for Selection and Use

To fully utilize the efficiency of this system, the following factors must be carefully considered in planning, selection, and use:

1. Scientific selection is fundamental:

Lifting capacity: Determined based on the maximum weight of a single item to be lifted, and considering future needs, leaving an appropriate margin.

Span and lifting height: The span of the crane is determined based on the factory structure or working area dimensions; the required lifting height is determined based on equipment, shelf height, and process flow.

Working class: Select the appropriate working class based on the expected frequency of use and load conditions, which relates to the durability and safety of the equipment. Environmental Adaptability: Consider the temperature, humidity, presence of dust, corrosive gases, or explosive hazards in the workshop environment, and select equipment with appropriate protection levels and explosion-proof characteristics.

Control Method: Choose between cab control, ground pendant control, or remote control based on operating habits and efficiency requirements.

2. Standardized Installation and Regular Maintenance:

Installation and commissioning must be carried out by qualified professional teams to ensure the accuracy of track laying and the safety and reliability of electrical wiring.

Establish and strictly implement a regular inspection and maintenance system, including daily checks, monthly inspections, and annual overhauls, focusing on key components such as wire ropes/chains, hooks, brakes, limit devices, and track conditions.

3. Safe Operation and Management:

Operators must receive professional training, be certified, and strictly adhere to safety operating procedures.

Overloading is strictly prohibited, and items being lifted must be securely fastened with a stable center of gravity.

Sound a bell or give a warning before the operation to ensure the safety of personnel in the work area.

Establish equipment safety management files to record usage, inspection, and maintenance information.

Conclusion

The combination of electric hoists and overhead cranes is a mature, efficient, and indispensable solution in the field of modern industrial material handling. Through aerial collaboration, they redefine the flow pattern of workshop logistics, perfectly combining power, precision, and range. A deep understanding of their technical characteristics, scientific selection and configuration based on actual needs, coupled with standardized installation, strict maintenance, and safe operation, will ensure that this system becomes a solid foundation for enterprises to improve production efficiency, guarantee operational safety, and achieve lean manufacturing and intelligent upgrades. In the process of moving towards "Industry 4.0" and intelligent manufacturing, this classic equipment combination will continue to play its irreplaceable key role.

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

kimliu@chnhoist.com

kimliu@chnhoist.com