Powerful Tools for Modern Industrial Material Handling—Hoist and Overhead Crane

Material handling is an indispensable and crucial part of modern industrial production, directly impacting not only production efficiency but also work safety and operating costs. Among numerous material handling devices, electric hoists and overhead crane systems, with their high efficiency, safety, and flexibility, have become standard equipment in various factories, warehouses, docks, and other locations. These two pieces of equipment work together to build an efficient and reliable material handling system.

Electric Hoists: Lightweight and Efficient Powerhouses

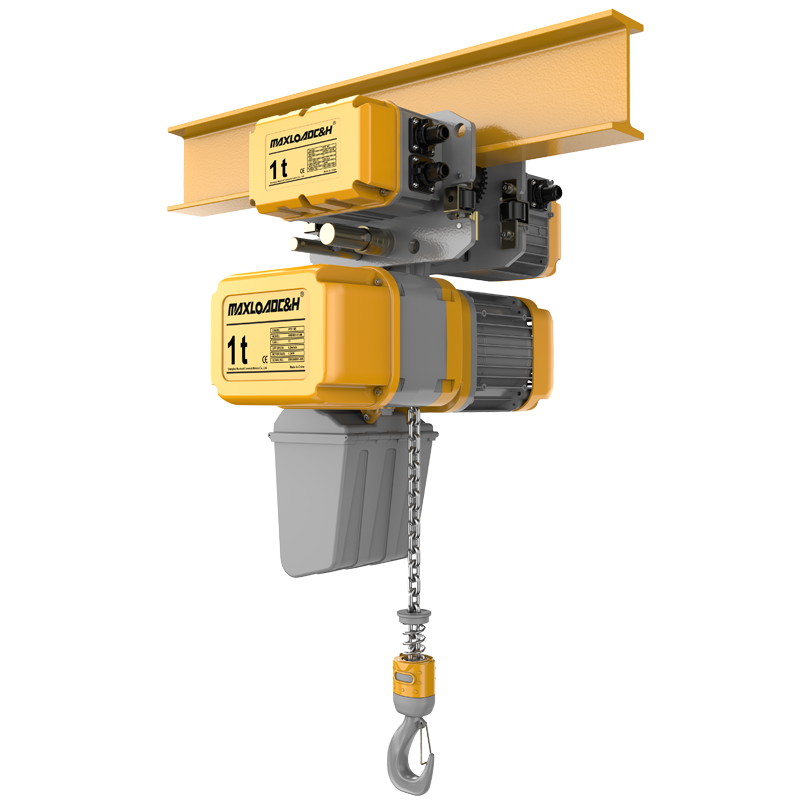

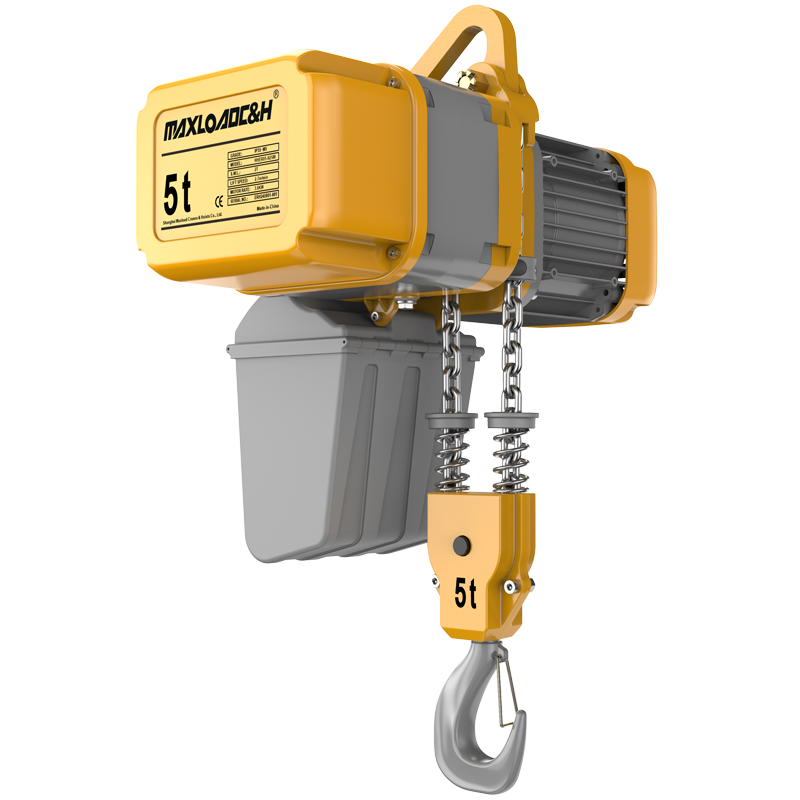

Electric hoists are compact and easy-to-operate lifting devices, mainly composed of a motor, reducer, brake, drum, and hook. Driven by electricity, they convert electrical energy into mechanical energy to lift heavy objects vertically. Based on their structural form, electric hoists are mainly divided into two categories: wire rope type and chain type.

Wire rope electric hoists use high-strength steel wire rope as the load-bearing medium, featuring high load-bearing capacity and large lifting height, suitable for handling heavy materials. Chain electric hoists, on the other hand, use alloy steel chains, resulting in a more compact structure and lighter weight, making them suitable for spaces with limited space. Both have their advantages, and the choice can be made based on specific needs in practical applications.

Electric hoists are designed with safety and reliability in mind. Modern electric hoists are typically equipped with multiple safety devices, including overload protection, limit switches, and emergency brakes, ensuring a timely shutdown in abnormal situations to prevent accidents. Simultaneously, their modular design makes maintenance more convenient, significantly reducing the equipment's lifecycle cost.

Overhead Crane System: A Flexible and Efficient Aerial Transport Platform

An overhead crane, also known as a bridge crane, is a lifting device that spans across workshops, warehouses, or material yards for the purpose of material handling. Its structure resembles a bridge, with both ends supported by two parallel elevated tracks, allowing longitudinal movement along the tracks; while the lifting trolley on the main beam can move laterally, forming a three-dimensional transport space covering the entire work area.

The overhead crane's structure mainly consists of a bridge frame, a trolley traveling mechanism, a crane traveling mechanism, and a lifting mechanism. The cable tray, as the main structure of the overhead crane, bears the entire load; the trolley traveling mechanism moves the entire overhead crane along the length of the factory building; the trolley traveling mechanism moves the lifting trolley laterally along the main beam of the cable tray; the lifting mechanism is usually an electric hoist, responsible for the vertical lifting and lowering of materials.

This unique design allows the overhead crane to move freely in three-dimensional space, achieving full coverage of the work area. Operators can control the overhead crane through ground operation, cab operation, or remote control, precisely completing the handling task according to the location and destination of the materials. Compared with traditional fixed lifting equipment, the overhead crane's flexibility is greatly improved, making it particularly suitable for occasions requiring frequent, multi-point handling.

The Perfect Combination of Electric Hoist and Overhead Crane

In practical applications, the electric hoist is often used as the lifting mechanism of the overhead crane, and the two are combined to form a complete material handling system. This combination fully leverages the advantages of each: the overhead crane provides a wide range of movement, while the electric hoist provides precise lifting control.

The advantages of this combined system are reflected in several aspects: First, it greatly improves work efficiency. Traditional manual handling or the use of simple lifting equipment is often time-consuming and labor-intensive, while electric hoists and overhead crane systems can complete the handling of large quantities of materials in a short time, significantly shortening the production cycle.

Secondly, it greatly reduces labor intensity. Operators only need to control the equipment to complete heavy handling tasks through the control device, reducing manpower input and avoiding occupational injuries that may be caused by heavy physical labor.

Thirdly, it improves handling accuracy. Modern electric hoists and overhead crane systems are usually equipped with precision control systems that can achieve millimeter-level positioning accuracy, which is especially important for operations such as precision assembly and installation of large components.

Finally, it optimizes space utilization. Compared with ground transportation equipment, overhead crane systems do not occupy ground space, making workshop layouts more flexible and material flow lines more rational.

Diverse Application Scenarios Electric hoists and overhead crane systems have a very wide range of applications, covering almost all industrial fields that require material handling:

In manufacturing plants, they are often used for raw material warehousing, the transfer of semi-finished products between processes, and the outbound delivery of finished products. Especially in industries such as automobile manufacturing, machining, and steel structure fabrication, the handling of large parts is inseparable from these devices. In the logistics and warehousing sector, overhead crane systems, in conjunction with various lifting devices, enable the rapid handling and stacking of standardized container units, significantly improving warehouse space utilization and inbound/outbound efficiency.

On construction sites, portable electric hoists and light-duty overhead cranes are commonly used for the vertical transport and on-site installation of building materials, playing an irreplaceable role, especially in high-rise building construction.

At ports and terminals, large double-girder overhead cranes and heavy-duty electric hoists form a powerful loading and unloading system, capable of efficiently handling various types of cargo, including containers and bulk cargo.

In energy facilities such as power plants and hydropower stations, these devices are not only used for component replacement during routine maintenance but are also key tools for equipment installation and repair.

Technological Development Trends

With the continuous advancement of industrial technology, electric hoists and overhead crane systems are also constantly evolving:

Intelligent control has become the mainstream trend. Modern equipment widely adopts frequency conversion control technology to achieve smooth start-up and precise stopping; some high-end systems are also equipped with intelligent functions such as automatic positioning, anti-sway, and path memory, further reducing operational difficulty and improving work efficiency.

Safety continues to improve. In addition to traditional mechanical safety devices, modern equipment incorporates more electronic protection measures, such as real-time monitoring systems, fault self-diagnosis, and remote alarms, constructing a multi-layered safety protection system.

Energy conservation and environmental protection have become key design priorities. The new generation of electric hoists and trolleys utilizes high-efficiency motors and energy feedback technologies to reduce energy consumption; simultaneously, noise control and material recyclability are receiving increasing attention.

Modular design simplifies installation and maintenance. Standardized interfaces and pre-assembled modules make equipment installation faster and facilitate future upgrades, modifications, and maintenance.

Conclusion: As core equipment in modern material handling, electric hoists and trolley systems are becoming increasingly important with industrial development. They not only improve production efficiency and reduce labor intensity but also provide strong guarantees for the safety and reliability of industrial production. In the future, with the further development of automation and intelligent technologies, these devices will become more intelligent, efficient, and easy to use, creating greater value for industrial production and logistics.

For enterprises, the rational selection and correct use of electric hoists and trolley systems are not only a necessary means to improve production efficiency but also an important way to achieve safe production and reduce operating costs. In the increasingly fierce market competition, efficient and reliable material handling systems have become an important part of the core competitiveness of enterprises, and deserve serious planning and investment from every industrial enterprise.

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

kimliu@chnhoist.com

kimliu@chnhoist.com