Electric Hoists and JIB Cranes: Efficient Lifting Solutions in Modern Industry

In modern industrial production and logistics, lifting equipment plays an indispensable role. From assembly workshops in large factories to busy port terminals, from warehousing and logistics centers to construction sites, safe and efficient material handling is key to ensuring smooth production processes. Among numerous lifting devices, electric hoists and JIB cranes, with their unique structures and functions, have become two widely used and important pieces of equipment. They each possess distinct technical characteristics and application advantages, together forming the cornerstone of modern industrial lifting operations.

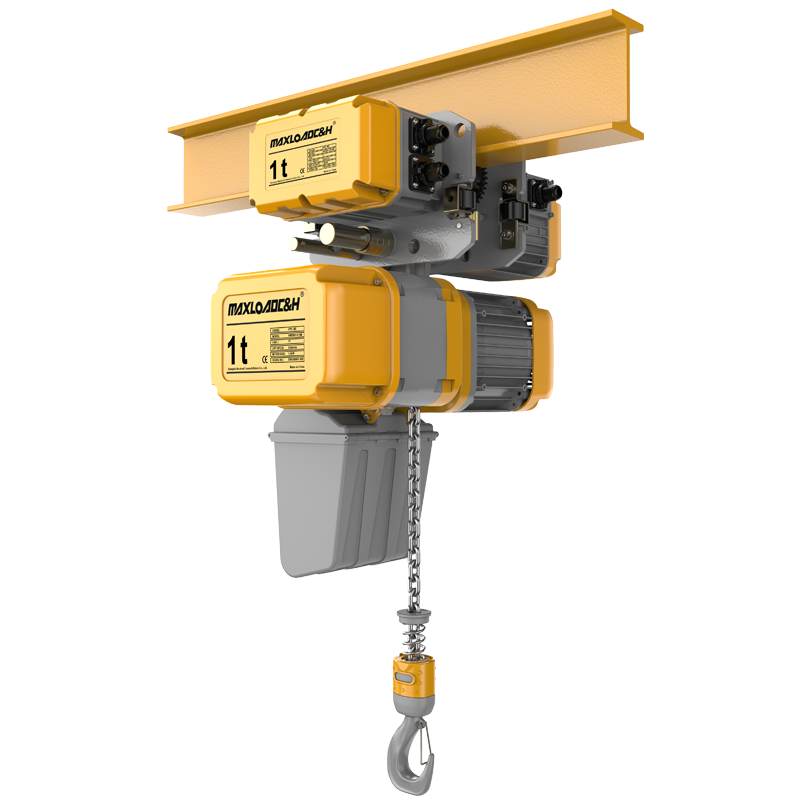

Electric Hoists: Flexible and Efficient Vertical Lifting Tools

In industrial applications, electric hoists exhibit great flexibility. They can be used independently, suspended from workshop roofs or I-beams via fixed supports, to complete lifting operations in fixed areas; more commonly, they are combined with various horizontal moving devices to form more powerful lifting systems. For example, installing an electric hoist on a manual or electric trolley that runs along I-beam tracks creates a simple bridge crane system covering a larger work area. This combination method is extremely common in machining, assembly workshops, maintenance sections, and warehouses, enabling flexible material handling in three-dimensional space.

JIB Cranes: Experts in Localized Material Handling

JIB cranes possess unique working characteristics—they can efficiently handle materials within a fan-shaped or circular area centered on the column and with the cantilever length as the radius. Compared to bridge cranes, which require large areas of rails and support structures, JIB cranes have a smaller footprint and simpler foundation engineering, making them particularly suitable for retrofitting existing workshops or for placement in areas with limited space.

JIB cranes are mainly classified according to their column fixing method: column-fixed foundation types provide the most stable support and the largest rotation range, suitable for frequent heavy-load operations; wall-mounted types save floor space and are suitable for material transfer along walls; mobile types are equipped with wheels or rails at the bottom, allowing flexible movement between different workstations and increasing equipment utilization. Cantilever structures also come in various forms to meet more complex process layout requirements.

In practical applications, JIB cranes are often placed at fixed workpoints such as machine tool loading and unloading points, welding stations, assembly lines, inspection tables, or packaging areas. Operators can easily move workpieces from one location to another within the cantilever's coverage area, significantly reducing the labor intensity of manual handling and improving the efficiency of inter-process coordination. Due to its precise positioning and simple operation, one person can complete the entire hoisting process, significantly saving labor costs.

Collaborative Operation: Building an Efficient Material Flow System

Although electric hoists and JIB cranes differ in their structural principles, they are not substitutes for each other in modern industrial production, but often work together to form complementary hoisting solutions. Understanding their core differences and applicable scenarios is crucial for equipment selection and system planning.

From a motion perspective, the core function of an electric hoist is vertical lifting, and horizontal movement requires a separate track system; whereas a JIB crane is essentially a composite motion system of "vertical lifting + horizontal rotation," with the cantilever's rotation providing a unique horizontal transport path. In terms of coverage, a single electric hoist with a linear track can cover long, narrow areas; a JIB crane focuses on high-density operations in circular or fan-shaped localized areas. Regarding installation conditions, electric hoists have higher requirements for the supporting structure above; JIB cranes have certain requirements for the ground or wall foundation. These differences are precisely what allow them to perfectly complement each other. In large workshops, a common solution is to use bridge cranes for cross-area material flow, while JIB cranes at each specific workstation handle precise loading, unloading, assembly, or flipping operations. For example, in an automotive parts production line, bridge cranes transport large blanks from the warehouse to different processing areas, while JIB cranes next to each machine tool accurately mount the workpieces onto the machine, process them, and then unload them. This "main artery" plus "capillary" logistics model maximizes material handling efficiency.

Selection and Application Considerations

Choosing the right lifting equipment for a specific application requires comprehensive consideration of multiple factors. For electric hoists, key considerations during selection include: the rated lifting capacity must exceed the maximum daily lifting load with a margin; the lifting height must meet the actual lifting distance requirements; the working level should match the actual working conditions; in addition, the working environment, power supply conditions, and control methods must also be considered.

The selection of JIB cranes is more complex: First, the cantilever length and rotation angle must be determined based on the process layout to ensure coverage of all necessary workstations without interference; second, the required bending and overturning resistance of the columns must be calculated based on the lifting capacity and cantilever length; the swivel support method affects the operator's feel and equipment cost; finally, the selection of the hoisting mechanism needs to be coordinated with the structural parameters of the JIB crane.

Safety is always the primary principle in lifting operations. Whether using electric hoists or JIB cranes, strict adherence to safety operating procedures is essential: check the equipment condition before operation, confirming the effectiveness of limit switches and brakes; do not overload, lift smoothly to avoid impact; ensure the lifting path is clear and unobstructed; perform regular maintenance, including lubrication, tightening, and checking the condition of critical components. Operators must undergo professional training and be certified to operate the equipment.

Technological Development Trends:

Electric hoists and JIB cranes are constantly evolving. Intelligentization is a significant trend: many new devices are equipped with sensors and IoT modules, capable of real-time monitoring of load, motor temperature, number of runs, and other data. The widespread adoption of frequency converter control technology makes starting, stopping, and speed adjustment smoother, reducing load sway.

Human-centered design is increasingly valued: ergonomically designed lightweight handles, large-screen displays, and intuitive fault diagnosis interfaces reduce operator workload and learning costs; low-noise motors and smooth operating mechanisms improve the working environment; modular design makes equipment installation, maintenance, and functional expansion more convenient.

In terms of green energy conservation, the application of technologies such as high-efficiency motors and energy feedback devices reduces equipment operating energy consumption; long-life design and the selection of recyclable materials reflect a life-cycle environmental protection concept.

Looking to the future, electric hoists and JIB cranes will continue to develop towards greater intelligence, precision, safety, and environmental friendliness. They will be more deeply integrated into digital factory systems, interconnected with platforms such as MES and WMS, becoming an important link in intelligent logistics. At the same time, specialized models catering to the needs of specific industries, such as cleanroom environments, food and pharmaceutical-grade corrosion protection, and extreme temperature conditions, will continue to emerge.

Conclusion: As fundamental equipment for modern industrial material handling, electric hoists and JIB cranes each address the challenges of vertical lifting and horizontal transport in different ways. Electric hoists, with their flexibility and adaptability, have become the core lifting unit in various crane systems; JIB cranes, with their unique rotating structure and high efficiency in localized operations, are irreplaceable in material handling at fixed workstations. Understanding their technical principles, mastering their selection criteria, adhering to safety regulations, and paying attention to their technological development trends are crucial for enterprises to optimize production processes, improve logistics efficiency, and ensure operational safety. In today's increasingly flexible, manufacturing and logistics efficiency-focused world, the rational configuration and application of these two types of equipment will be a significant boost to enhancing enterprise competitiveness.

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

kimliu@chnhoist.com

kimliu@chnhoist.com