The Two Wings of Modern Industrial Lifting Operations

In modern factory workshops, beneath the steel beams of large logistics warehouses, and on the construction sites of major infrastructure projects, one often sees a type of equipment, either soaring through the air or steadily lifting and lowering, precisely transporting tons of materials and workpieces to designated locations. Their "heart" and "body"—the electric hoist and the overhead crane—together constitute the backbone of vertical and horizontal material handling in industry. Although they often work together, each performs its own function; their precise coordination and continuous innovation profoundly reflect modern industry's relentless pursuit of efficiency, safety, and intelligence.

I. Core and Carrier: Definition and Symbiotic Relationship

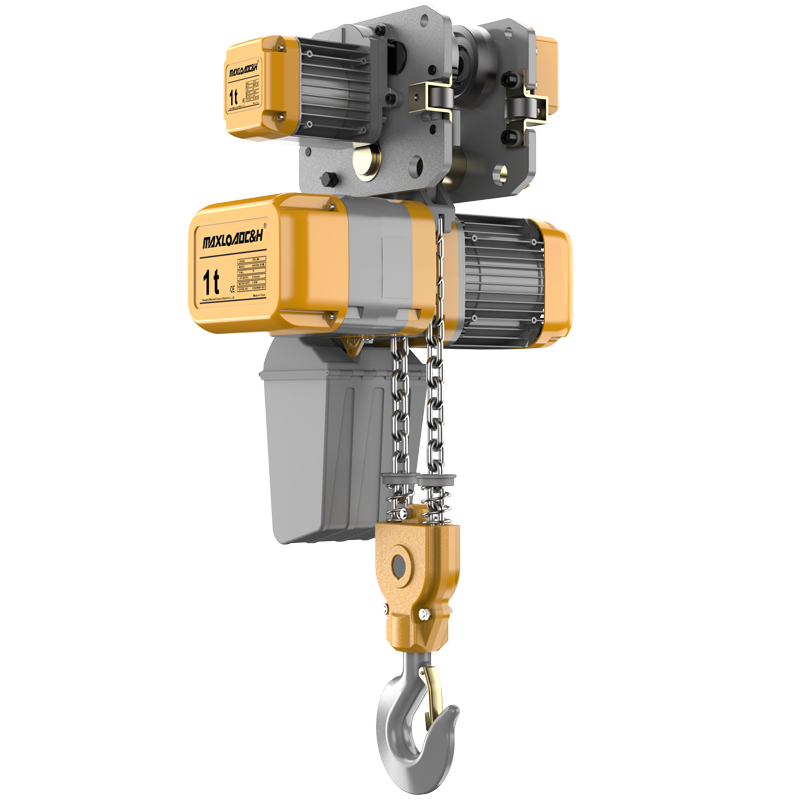

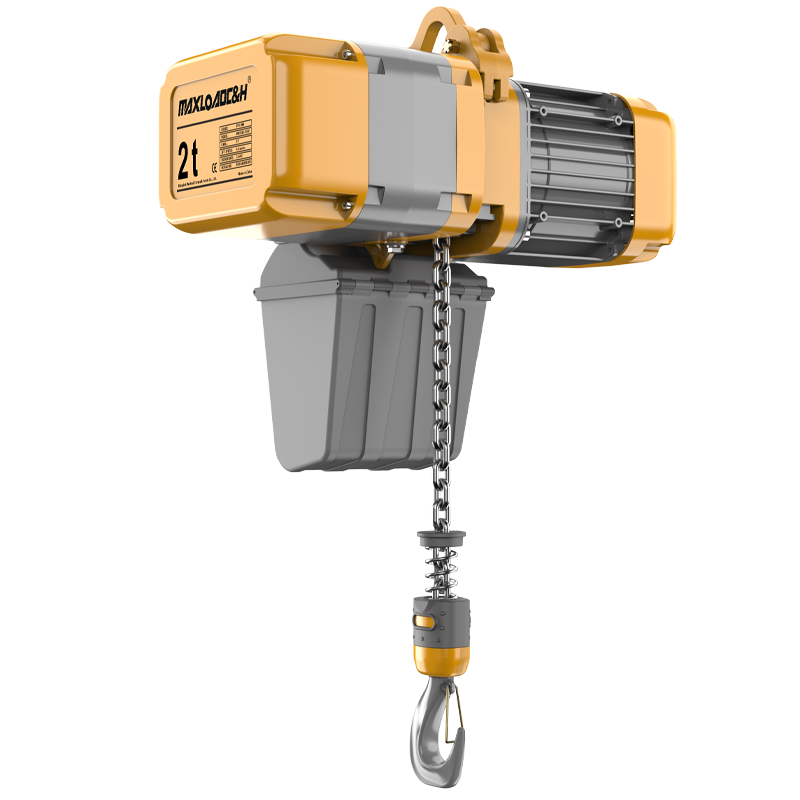

First, let's clarify these two core concepts. An electric hoist is a compact, specialized, lightweight lifting device. It typically integrates core components such as a motor, reduction gear, drum, hook, and braking system into one or more housings, primarily providing a powerful vertical lifting force. It can be imagined as a highly engineered "powerful arm," whose core mission is to overcome gravity and safely lift and lower heavy objects.

Overhead cranes, also known as bridge cranes, are a much larger and more complex system. Their main body is a "bridge" spanning tracks on both sides of a workshop or warehouse. The bridge's ends are supported by end beams on traveling wheels, allowing for longitudinal movement along elevated tracks. A trolley, capable of lateral movement, is typically mounted on the main beam. The overhead crane's "grabbing" function is achieved through an electric hoist mounted on this trolley. Therefore, an overhead crane is essentially an "aerial robot" providing a precisely positioned moving platform in a two-dimensional plane, while the electric hoist is the terminal actuator that completes its final "grabbing-lifting-lowering" action.

The relationship between the two is a typical example of symbiosis and integration: the electric hoist provides the overhead crane with its core lifting capacity; the overhead crane, in turn, expands the electric hoist's working space and coverage area without blind spots. Without the hoist, the overhead crane is merely an unloaded moving platform; without the overhead crane's load-bearing and transporting capabilities, the hoist's effective radius would be greatly limited. This combination achieves an expansion of operational dimensions from "point" to "surface" and then to "space."

II. Core Technologies: Key Components and Evolution of Each

Despite their collaborative operation, electric hoists and overhead cranes have different technological focuses and are constantly evolving.

The core technology of electric hoists lies in "lifting":

Lifting Mechanism: The core is a motor driving a drum to wind wire rope via a high-efficiency reducer. Currently, the application of modularly designed reducers and high-strength anti-rotation wire ropes significantly improves transmission efficiency and reliability. Chain electric hoists, due to their light weight and compact structure, have unique advantages in frequent operations and space-constrained situations.

Power and Control System: Traditional conical rotor motors are widely used due to their built-in braking function. However, with the popularization of variable frequency speed control technology, the use of ordinary motors combined with frequency converter control is increasingly common. This allows for extremely smooth control of start, stop, and running speed, greatly reducing load sway and achieving millimeter-level precise positioning, making it particularly suitable for precision assembly and fragile item handling.

Safety and Protection Devices: In addition to basic mechanical brakes, modern electric hoists often integrate overload protection, limit protection, and phase sequence protection functions. Some advanced designs also feature real-time load monitoring and display systems, providing operators with crucial data.

The core technology of overhead cranes lies in "load bearing" and "operation":

Bridge Structure: The main beam is the key technology, and its design must balance strength, stiffness, and self-weight. Box girders have become mainstream due to their excellent torsional resistance and load-bearing capacity. The application of modern design methods, such as finite element analysis, has made structures lighter while meeting safety requirements. Double-girder overhead cranes have good stability and are suitable for large tonnage and large span applications; single-girder overhead cranes have simple structures and lower costs, and are widely used for medium and light loads and medium and short spans.

Traction and Drive Mechanisms: The movement of both the main and auxiliary trolleys needs to be smooth and precise. The centralized drive is gradually being replaced by a three-in-one drive. Three-in-one drive offers flexible layout, good synchronization, and easy maintenance, representing the current mainstream direction.

Overall Control System and Human-Centered Design: Modern overhead cranes have evolved from traditional cab control to ground remote control and even remote control integrated with factory automation systems. Anti-sway control technology, automatic positioning systems, and intelligent collision avoidance systems have become hallmarks of high-end overhead cranes. Furthermore, ergonomically designed cabs, fully covered walkways, and guardrails all reflect a high level of attention to operator safety and comfort.

III. Application Areas: The Ubiquitous Foundation of Industry

This "golden combination" is used in almost all heavy industries and some light industries:

Heavy Manufacturing and Assembly: In machinery, metallurgy, shipbuilding, and automobile manufacturing workshops, they are responsible for handling steel plates, engines, and large castings, and participate in equipment assembly and rotation.

Logistics and Warehousing: In large warehouses, container terminals, and railway freight yards, they are used for stacking, loading and unloading containers and large cargo.

Energy and Infrastructure Construction: Equipment installation and maintenance in hydropower stations and thermal power plants; hoisting of prefabricated components on bridges and construction sites.

Special and Professional Environments: Explosion-proof hoists and overhead cranes are used in hazardous areas such as chemical and oil and gas plants; cleanroom types are used in the electronics and pharmaceutical industries; low headroom designs are used for the renovation of old factories with limited space.

IV. Future Outlook: Integration of Intelligent and Green Technology

Technological progress is endless, and the development of electric hoists and overhead cranes is showing clear trends:

Intelligent Technology: Integrating sensors and IoT modules to achieve real-time monitoring and predictive maintenance of equipment health status. Through data collection and analysis, operational efficiency is optimized and unexpected downtime is prevented.

Precise Control Automation: Deeply integrated with factory MES and WMS, after receiving instructions, it automatically travels to designated coordinates to complete fully automated grabbing and storage, becoming a key link in smart factory logistics.

Green and Efficient Technology: Adopting higher energy efficiency motors, energy feedback devices, LED lighting, etc., to reduce overall energy consumption. The lightweight structural design saves materials and reduces operating energy consumption.

Humanization and ease of use: Augmented reality-assisted operation and maintenance guidance, a more ergonomic interface, and lower noise levels will further enhance the operating experience and safety.

Conclusion From the roaring steel mills to the quiet chip workshops, from bustling ports to towering power plants, the electric hoist and overhead crane, this silent "power duo," have always been the backbone supporting the flow of materials in modern industry. They are not merely combinations of steel machinery, but a comprehensive embodiment of mechanics, electricity, materials science, and cybernetics. With the deepening of the intelligent wave, this traditional "giant force" is being infused with "intelligent brains," transforming from simple "power executors" to "intelligent logistics nodes," continuing to play an irreplaceable key role in enhancing humanity's ability to transform the world. Every smooth lifting and precise displacement they perform silently writes a cornerstone chapter in the efficiency and reliability of modern industry.

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

kimliu@chnhoist.com

kimliu@chnhoist.com