Electric Hoists and Jib Cranes: High-Efficiency Collaboration

Material handling is an essential part of modern industrial production, warehousing and logistics, and construction. How to safely, efficiently, and accurately move, position, and assemble heavy objects has always been a focus of industry attention. Electric hoists and jib cranes, as two classic lifting devices, each have significant advantages. When they are scientifically combined, they can achieve a synergistic effect greater than the sum of their parts ("1+1>2"), becoming a key solution for improving material handling efficiency in modern workshops, warehouses, docks, and other locations.

I. Lifting Experts Each Performing Their Duties

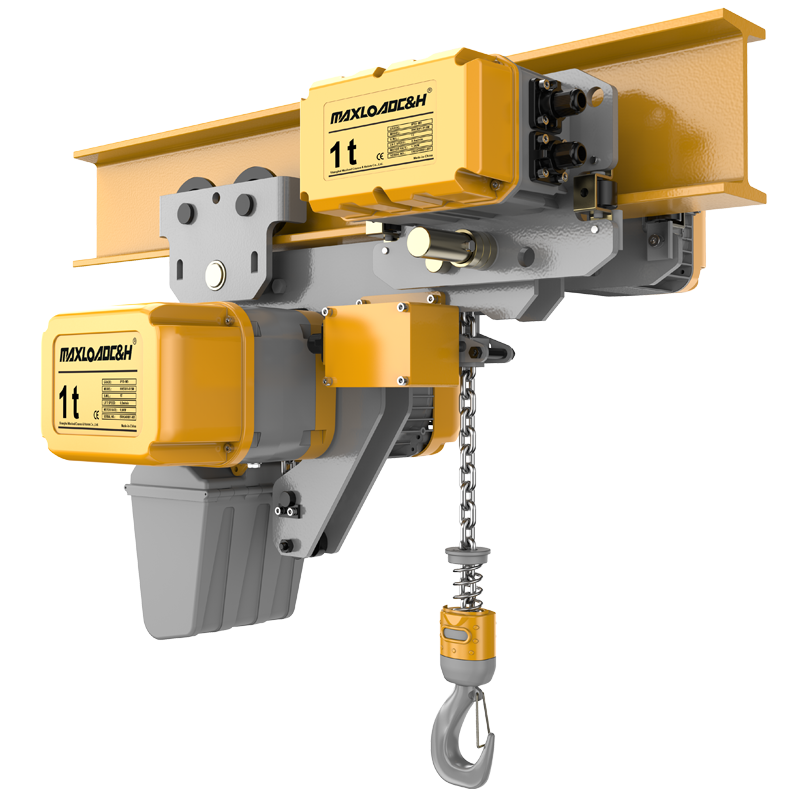

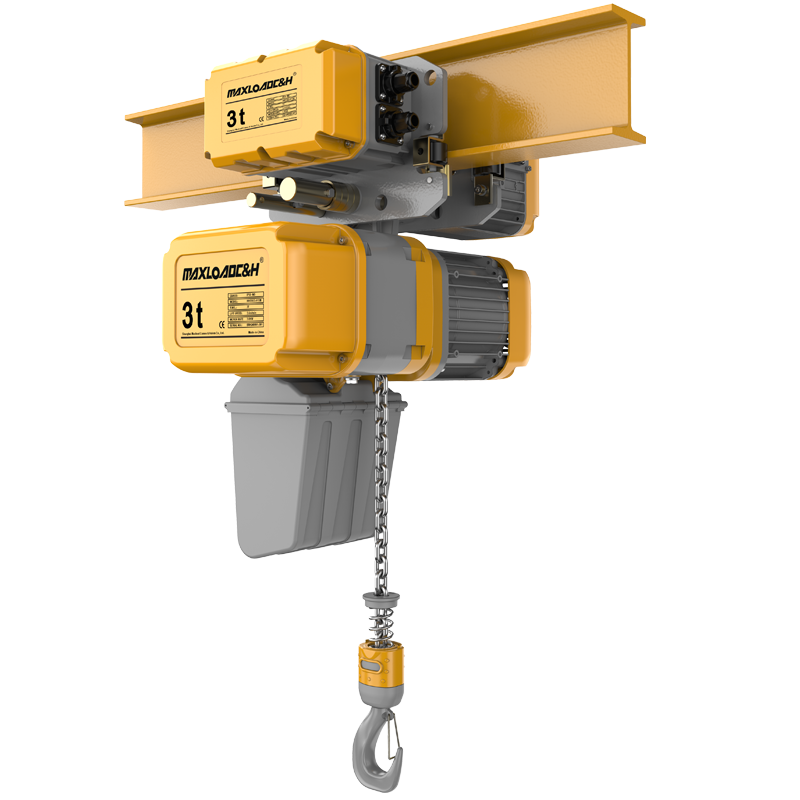

Electric hoists are small and lightweight lifting devices, typically composed of a motor, transmission mechanism, or sprocket and hook. They are compact, lightweight, and easy to operate. They can be used independently on fixed supports or as the lifting mechanism for various bridge and gantry cranes. Electric hoists are widely used for lifting, moving, and loading/unloading heavy objects due to their fast lifting speed, precise positioning, and ease of control.

A jib crane is a type of rotary crane with a special structure, mainly composed of a column, a slewing boom, a slewing drive, and an electric hoist. Its most significant feature is that the boom can rotate around the column, covering a fan-shaped or circular area. Jib cranes have a small footprint, are flexible in operation, and can fully utilize site space, making them particularly suitable for situations where the work point is relatively fixed but requires movement and precise positioning within a certain range.

II. Complementary Functions, Forming an Efficient Working Unit

The collaboration between the electric hoist and the jib crane is not a simple mechanical addition, but rather a process of functional integration and process optimization, forming an efficient and flexible material handling unit.

1. Combination of Spatial Coverage and Precise Positioning The jib crane's slewing boom provides a wide working range on the horizontal plane, while the electric hoist, running on the jib beam, is responsible for vertical lifting and precise lateral adjustments. This combination overcomes the limitation of traditional fixed hoists, which can only perform point-to-point vertical lifting, enabling material storage and retrieval at any location in three-dimensional space. 1. **Operators can easily lift heavy objects to any designated location within the coverage area by controlling the rotation of the cantilever and the operation of the electric hoist, greatly reducing the hassle of manual handling or secondary positioning with the aid of other tools.

2. Efficient Flow Operations: This collaborative model demonstrates its advantages on production assembly lines. For example, parts that have completed preliminary processing at one workstation can be quickly lifted by the cantilever crane, along with the electric hoist, and rotated to the next workstation for assembly. The entire process is smooth and continuous, effectively shortening the time workpieces spend between processes and improving overall production efficiency. In warehousing scenarios, it can be used to retrieve goods from shelves or specific areas and rotate them to the packaging area or transport vehicles, optimizing warehousing operations.

3. Flexible Response to Complex Environments: In workshops with limited space and many obstacles, or in situations such as docks and repair shops where lifting needs to bypass the barriers, the rotational characteristics of the cantilever crane, combined with the lifting capabilities of the electric hoist, allow for flexible "detours" and precise delivery of materials to the target location—something many large cranes cannot achieve.

III. Multiple Improvements in Safety, Economy, and Efficiency

1. Significantly Improved Operational Efficiency and Flexibility

Traditional single-equipment systems often require manual handling or other machinery for transport, involving multiple steps and significant time consumption. The integrated use of electric hoists and jib cranes allows one person to complete the entire operation of material handling, including picking, moving, positioning, and unloading, reducing equipment waiting time and personnel coordination time. This results in extremely high operational flexibility, particularly suitable for medium-to-high frequency, medium-to-light tonnage lifting tasks.

2. Optimized Space Utilization and Reduced Investment Costs

Compared to bridge cranes that require large rails, the system of a column-mounted jib crane combined with an electric hoist has a smaller footprint, lower requirements for factory structure, and is easier to install. It can fully utilize workshop columns or walls for installation, and can even be installed directly next to existing equipment to serve specific machine groups, achieving a "space-filling" layout, saving valuable production floor space, and making the overall investment and maintenance costs more economical.

3. Enhanced Operational Safety and Controllability

Electric hoists are typically equipped with multiple safety devices such as overload protection, limit protection, and phase sequence protection. The cantilever crane's structure also ensures stable operation under its design load. Together, these two aspects make the entire lifting process completely controllable. Operators on the ground can clearly observe the entire process via remote control or a button station, staying away from the load and avoiding the safety risks associated with traditional lifting methods. Precise control also reduces collision damage to materials and equipment.

4. Reduced Worker Labor Intensity

This collaborative system transforms heavy physical labor into simple equipment operation. Workers no longer need to exert effort pushing and pulling heavy objects or perform dangerous climbing operations, fundamentally improving working conditions and reducing excessive physical demands on operators.

IV. Typical Application Scenarios

Machinery and Assembly Workshops: Used for loading and unloading machine tools, transferring parts between processes, and assembling small equipment.

Warehouses and Logistics Centers: Used for stacking, destacking, and loading/unloading vehicles, especially for storing and retrieving goods in specific areas.

Equipment Repair and Maintenance Areas: Facilitates partial disassembly of large equipment and replacement of heavy components, such as motors and gearboxes.

Automotive repair shops and manufacturing processes: Lifting engine and transmission assemblies, assembling tires, or positioning body parts.

Laboratories and testing centers: Safely and smoothly lifting precision instruments or test samples.

V. Key Points for Scientific Selection and Collaboration

To achieve optimal collaboration between electric hoists and jib cranes, the following should be considered during selection and configuration:

Parameter Matching: The rated load, rotation radius, and rotation angle of the jib crane must meet the requirements of the working area. The lifting capacity, lifting height, operating speed, and working level of the electric hoist must match the jib crane, with a slight margin. Typically, the electric hoist is selected as a standard component of the jib crane.

Structural Form Selection: Select a fixed column jib crane, wall-mounted jib crane, or mobile jib crane based on site conditions. For the electric hoist, select either a wire rope type or a chain type, depending on requirements.

Control System Integration: Ensure that the rotation control of the jib crane and the lifting and travel control of the electric hoist are integrated into the same operating interface, enabling one-handed or simple linkage operation and avoiding cumbersome switching operations.

Installation and Maintenance: Installation should be performed by qualified personnel to ensure a solid foundation for the support column and that the cantilever's level meets requirements. Regular maintenance should be performed on the slewing mechanism, electric hoist brakes, wire ropes/chains, limit devices, etc., to ensure the entire system is in good working order.

VI. Future Development Trends

With the development of industrial automation and intelligence, the collaboration between electric hoists and cantilever cranes is showing new trends. For example, integrating an intelligent anti-sway control system can automatically suppress hook sway during high-speed movement, achieving faster and more accurate positioning; adding sensors and IoT modules enables real-time monitoring and predictive maintenance of equipment status, load, and operating data; and combining with or along a track system to form a mobile automated workstation, further expanding the operating range and application scenarios.

In conclusion, the collaboration between electric hoists and jib cranes represents a classic and highly efficient combination in modern material handling technology. It cleverly integrates vertical lifting with horizontal rotation and transport, solving the core problems of precise material positioning and efficient material flow within a relatively simple mechanical structure. This collaborative model not only embodies the "suitable is best" equipment selection philosophy but also serves as a practical tool for lean manufacturing and process optimization. Against the backdrop of manufacturing upgrades and improved logistics efficiency, a deep understanding and rational application of this collaborative system will undoubtedly bring tangible safety, efficiency, and economic benefits to various industries.

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

kimliu@chnhoist.com

kimliu@chnhoist.com