Electric Hoists and Overhead Cranes: Key Players in Modern Industry

Lifting machinery plays an indispensable role in many fields, including modern industrial production, construction, logistics, and warehousing, as well as the installation of large equipment. Like the "arms" of industrial giants, they easily lift, precisely move, and safely place heavy objects, greatly improving work efficiency and reducing manpower burden and safety risks. Among various lifting equipment, electric hoists and overhead cranes are the two most widely used types. Although their names are often used interchangeably, they are closely related yet significantly different in structure, function, and application. This article will provide an in-depth analysis of these two types of equipment to help you better understand their characteristics and applicable scenarios.

I. Core Analysis

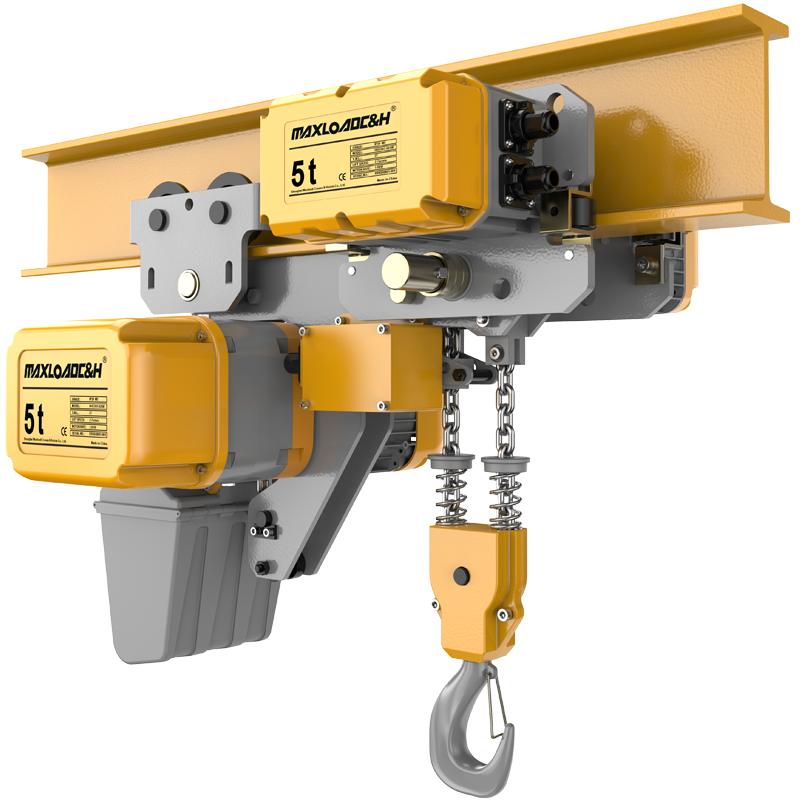

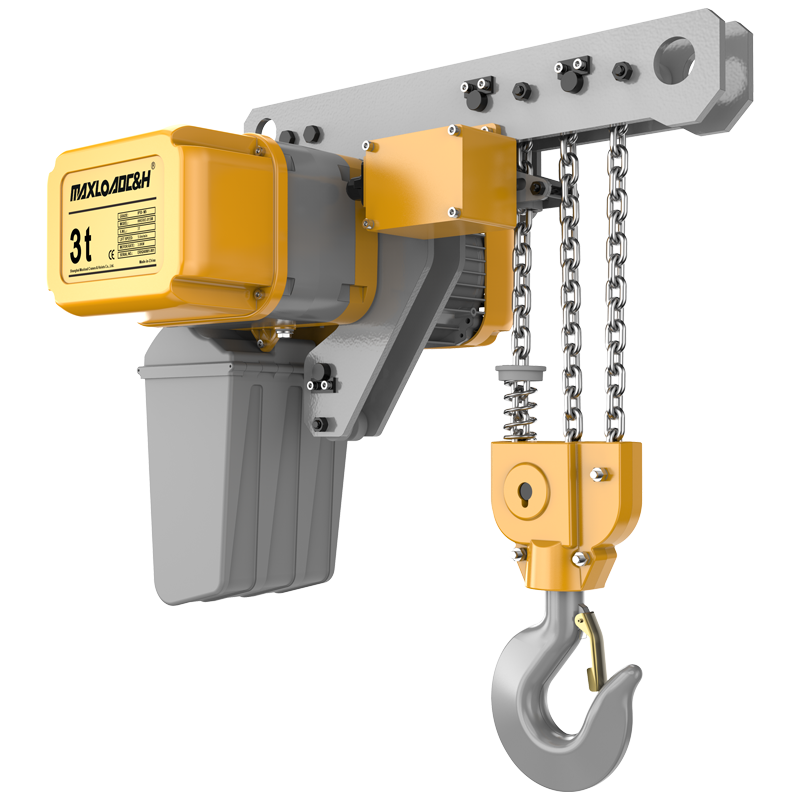

A typical electric hoist mainly consists of the following parts:

Drive Motor: Provides the power source, usually divided into conical rotor motors and ordinary motors.

Reduction Mechanism: Reduces the motor's high speed, converting it into powerful lifting torque.

Drum and Wire Rope/Chain: Winds the load-bearing component (wire rope or chain), achieving hook lifting and lowering through forward and reverse rotation.

Hook Device: The component that directly connects to the load.

Electrical Control System: Includes a control box, push-button switches, or a remote control for operating the lifting and travel.

Traveling Mechanism: Some electric hoists come with a trolley, allowing linear movement on I-beam rails, expanding their working range.

Main Features:

Compact Structure, High Integration: Power, transmission, and winding mechanisms are highly integrated into a lightweight housing.

Flexible Installation: Can be used independently or as a key component on a larger crane.

Easy Operation: Mostly uses inching control, providing rapid response and precise positioning.

Wide Lifting Capacity Range: From several hundred kilograms to tens of tons, but typically used for small to medium tonnage applications.

Typical Application Scenarios:

Point-to-point lifting of parts in workshops and assembly line workstations.

Material handling in warehouses and garages.

In conjunction with simple gantry cranes or cantilever cranes, forming a small-scale lifting system.

As the core lifting mechanism of the overhead crane.

II. System Integration

An overhead crane, also known as a bridge crane, is a more complex and complete material handling system. Like a movable "bridge," it spans across a workshop or warehouse, covering a rectangular area in three-dimensional space.

Basic Structure and Working Principle: A standard double-girder overhead crane typically comprises three main operating mechanisms:

Bridge: The main metal structure, spanning both sides of the factory building, is composed of main beams and end beams. It bears the weight of all mechanisms and loads, and moves longitudinally along elevated tracks on both sides of the factory building via the trolley traveling mechanism.

Lifting Trolley: Moves laterally along the main beam tracks of the bridge. The trolley integrates core components—an electric hoist, the trolley traveling mechanism, and its control system.

Electrical Control System: Includes the operator's cab, ground-based follow control, or remote control, coordinating the combined movements of the trolley, crane, and lifting mechanism to achieve the lifting of heavy objects at any point within the working area.

Main Features:

High Space Utilization: Does not occupy ground working area, fully utilizing the space above the factory building.

Large Working Range: Through the combined movement of the trolley and crane, it can cover almost the entire area under the factory building's span.

Powerful Functionality and High Load Capacity: Designed for lifting extremely heavy loads and can be equipped with various lifting tools such as auxiliary hooks, grab buckets, and electromagnetic chucks.

Systematic and Customized: Specially designed according to the needs of workshop span, lifting height, work schedule, and environment.

Typical Application Scenarios: Handling and assembling raw materials, semi-finished products, and finished products in heavy machinery manufacturing and metallurgical industries.

Equipment installation and maintenance in power plants and boiler rooms.

Container or heavy cargo handling in large warehousing and logistics centers.

Almost any industrial site requires frequent, heavy-duty lifting operations in a large, fixed area.

III. Clarifying Relationships

Core Differences:

Identity: An electric hoist is a "component" or "independent tool"; a trolley is an "integrated system."

Motion Dimensions: Fixed hoists can only perform vertical lifting; hoists with trolleys can perform "horizontal one-dimensional + vertical" movement; trolleys can achieve "horizontal two-dimensional + vertical" omnidirectional coverage movement.

Scale and Control: Hoists are generally simple in structure and directly controllable; overhead cranes have complex structures, requiring the coordination of multiple mechanisms and necessitating more advanced control systems.

Internal Connection: In most general-purpose overhead cranes, the lifting function is accomplished by one or more electric hoists. It can be said that the electric hoist is the heart of the overhead crane's "lifting and lowering" function. However, the overhead crane is a much larger platform, providing this "heart" with a stage for lateral movement and a robust support structure.

How to Choose: Electric Hoist or Overhead Crane?

The choice depends on your specific needs:

Choose a standalone electric hoist when:

The working range is fixed, requiring lifting operations only at a single point or along a line.

The budget is limited, and there is already a suitable support structure in the workshop.

As a temporary, auxiliary, or supplementary lifting device.

Space is limited, making it impossible to install a large overhead crane structure.

Choose an overhead crane when:

Need to perform comprehensive material handling over a large area within a fixed factory or warehouse.

Frequent lifting tasks, heavy loads, and high requirements for positioning accuracy and work efficiency.

The process requires the movement of heavy objects between multiple workstations.

The goal is to maximize floor space utilization, achieve separation of personnel and machinery, and improve safety.

IV. Safety and the Future

Whether using electric hoists or overhead cranes, safety is always the top priority. It is essential to ensure that equipment is installed, inspected, and regularly maintained by qualified organizations. Operators must be professionally trained, strictly adhere to safety procedures, check equipment status before operation, avoid overloading and oblique pulling, and ensure clear lifting paths and personnel safety.

Looking to the future, with the advancement of Industry 4.0 and smart manufacturing, electric hoists and overhead cranes are also developing towards intelligence and the Internet of Things (IoT). These technological advancements will further drive innovation in logistics and material handling, injecting stronger momentum into industrial production.

In summary, electric hoists are flexible and efficient "lifting grippers," while overhead cranes are comprehensive "space transport networks" built upon them. Understanding their respective characteristics and synergistic relationships helps companies make more scientific, economical, and safer choices in equipment selection, workshop planning, and logistics optimization, thereby effectively improving core productivity.

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

kimliu@chnhoist.com

kimliu@chnhoist.com