The Core Force and Wise Choices in Industrial Material Handling

In modern factory workshops, bustling construction sites, and efficient logistics warehouses, we often see them—either gracefully rising and falling beneath I-beams or majestically spanning the workshops. Electric hoists and cranes, as core equipment in the field of material handling, are like the "steel arms" of the industrial system, silently supporting various production activities from parts assembly to the hoisting of large components. Although often mentioned together, they have fundamental differences and unique synergies in structure, capacity, and application. Understanding their essence is not only about technical knowledge but also crucial for improving operational efficiency, ensuring safety, and optimizing resource allocation.

I. Clarifying Basic Concepts

First, let's define these two core concepts.

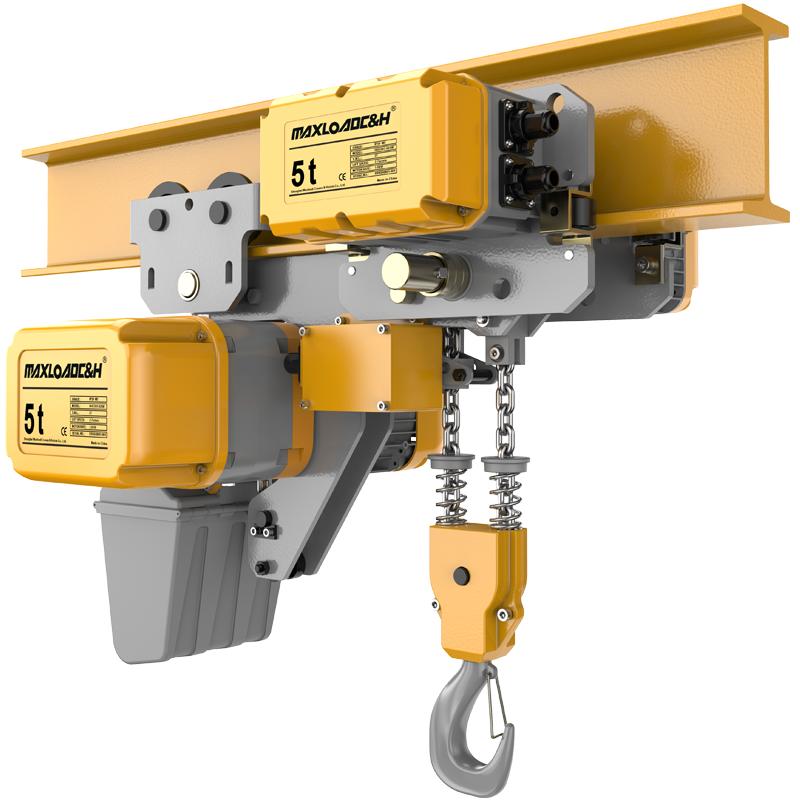

An electric hoist is a compact, lightweight, and flexible lifting device. It typically consists of a motor, reduction gear, drum (or sprocket), and hook, integrating power, transmission, and execution mechanisms. Electric hoists primarily provide a single vertical lifting motion, and sometimes can also perform limited linear horizontal movement along pre-installed simple tracks. Its core characteristics are integration and modularity. It is often used as an independent lifting unit or as a core component in more complex lifting machinery. Depending on the lifting medium, common types include wire rope electric hoists and chain electric hoists.

A crane, however, is a broader and more systematic concept. It refers to a multi-action machine capable of vertically lifting and horizontally moving heavy objects within a certain space. A complete crane is typically a complex system, including a metal structure, hoisting mechanism, traveling mechanism, luffing mechanism, slewing mechanism, and corresponding electrical control systems and safety devices. Cranes create a three-dimensional lifting space, and their core characteristics are functional integration and spatial coverage.

In short, an electric hoist is essentially a specialized "lifting actuator," while a crane is a fully functional "material handling system." In many bridge and gantry cranes, the core lifting mechanism is handled by one or two electric hoists. This relationship is similar to that of a car engine and the entire vehicle: the electric hoist is the powerful "heart," while the crane is the "body" that supports this heart and gives it omnidirectional movement capabilities.

II. Technical Characteristics and Applications of Two Types of Equipment

Electric Hoists: Flexible and Efficient Point-to-Point Lifting Experts

Technical Characteristics:

Compact Structure and Lightweight: Ingenious design, small footprint, and low foundation requirements, making them ideal for space-constrained applications.

Easy Installation and High Adaptability: Can be used independently or suspended on various supports, curved rails, or cantilever arms to form simple lifting devices.

Simple Operation and Maintenance: Typically uses inching control, intuitive and easy to learn. Modular design makes daily inspection and maintenance relatively convenient.

Focused Lifting Capacity Range: Covers a wide range of common specifications.

Relatively Moderate Working Level: Suitable for infrequent operations.

Typical Application Scenarios:

Workshop Workstation Lifting: Lifting parts and molds alongside the production line.

Maintenance and Assembly: Precise positioning and installation at equipment maintenance points and assembly sections.

Warehouse Material Storage and Retrieval: Used in conjunction with cantilever cranes or simple gantry cranes for stacking and loading/unloading operations.

As a core component, Built into bridge cranes, gantry cranes, and jib cranes, serving as the standard lifting mechanism.

Crane: A comprehensive "space transport" system

Technical Features:

Integrated functions, diverse movements: Integrates lifting, traveling, and slewing movements, enabling precise positioning within a three-dimensional workspace.

Complex structure, high load-bearing capacity: Possesses a robust metal structure capable of withstanding its own weight, the load being lifted, and various dynamic loads generated during operation.

Advanced control system: Typically equipped with a more complex electrical control system, enabling remote control, automated programming, and even intelligent scheduling.

Wide range of working levels: From light to extremely heavy, meeting the requirements of various operating frequencies and load rates.

Requires specialized design and installation: Classified as special equipment, requiring strict foundation construction, installation, commissioning, and compliance acceptance.

Main Types and Applications:

Bridge Cranes: Run on rails on both sides of workshops and warehouses, covering a rectangular work area. The most common "overhead crane" in manufacturing plants.

Gantry Cranes: Equipped with outriggers, running on ground rails, resembling a "door frame."

Flexible beam cranes (modular cranes): Utilizing lightweight, high-strength profiles and a modular design, they are lighter and more flexible than traditional bridge cranes, making them particularly suitable for high-frequency, high-precision assembly line operations.

III. How to Leverage Each Other's Strengths

Their synergistic relationship is reflected in the fact that the electric hoist provides the crane with efficient and reliable core lifting functions, while the crane expands the application scope of the electric hoist. For example, a standard double-girder bridge crane is actually a collaborative system composed of the bridge (trolley) structure, two traverse trolleys, and electric hoists mounted on the trolleys.

IV. Making Wise Decisions Based on Needs

Faced with specific needs, how do you choose between these two or between different crane types? Here are some key considerations: Lifting capacity and working space: This is the primary factor. For lifting operations only at fixed points or along short straight distances, using an electric hoist alone or with a simple support frame is an economical and efficient choice. When it is necessary to cover a workshop, an open area, or to lift heavy objects in three-dimensional space, an appropriate crane must be selected.

Usage Frequency and Work Intensity: For assembly lines requiring hundreds or even thousands of lifting operations daily, choose cranes with high working class and more durable designs. For occasional maintenance points, a standard electric hoist may suffice.

Factory Conditions and Infrastructure: The height, column spacing, and ground load-bearing capacity of the existing factory determine whether a bridge crane can be installed and its span. Open spaces without suitable support structures may be more suitable for gantry cranes or mobile cranes.

Positioning Accuracy and Control System Requirements: For precision assembly and laboratory environments with extremely high precision requirements, anti-sway control systems, variable frequency speed control, or even automated positioning intelligent cranes may be necessary. For general material handling, conventional control methods can be used.

Total Cost of Ownership (TCO): Consider not only the initial purchase cost but also installation costs, energy consumption, daily maintenance, and the value derived from long-term reliability and efficiency improvements. Sometimes, a high-efficiency crane with a higher initial investment may offer a better long-term return due to the increased production cycle time and labor savings it provides.

In conclusion, the choice between electric hoists and cranes is not simply a matter of superiority or inferiority, but rather the cornerstone and pillar of modern industrial material handling systems. Electric hoists, with their modular design and focused performance enhancements, demonstrate exceptional flexibility and applicability; cranes, with their systematic integration and comprehensive spatial coverage, embody the scale and power of industrial manufacturing. From micro-level workstations to macro-level logistics, they together weave an efficient and safe material flow network.

When choosing between them, move beyond the "equipment" itself and return to the fundamental "needs": carefully analyze your material characteristics, process flow, spatial layout, and operational objectives. Only by embedding the right equipment into optimized processes can these "steel arms" truly become powerful tools for improving quality, increasing efficiency, and reducing costs, allowing businesses to seize opportunities in fierce market competition.

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

0086 156 1824 5535

kimliu@chnhoist.com

kimliu@chnhoist.com